Thermal shock test chambers are widely used across industries such as semiconductors, automotive electronics, new energy batteries, and aerospace. While many companies focus primarily on the purchase price and core specifications when evaluating a chamber, they often discover after deployment that the total cost of ownership (TCO) far exceeds the initial investment. Hidden costs, if not properly assessed in advance, can place significant strain on both operational budgets and project timelines.

This article examines five key areas of hidden costs associated with thermal shock test chambers to help companies make more informed, forward-looking decisions.

Energy Consumption Costs

Energy consumption is the most visible long-term expense for companies operating thermal shock test chambers. These chambers require rapid transitions between extreme high and low temperatures within seconds, which forces both the refrigeration and heating systems to run at full capacity. In high-frequency testing environments, power usage can be several times higher than that of conventional temperature-humidity chambers.

If buyers focus only on chamber volume and temperature range without considering energy efficiency or power-saving designs, they may face substantially higher electricity bills over time. Some manufacturers integrate dual-system energy-saving modes, inverter controls, and other advanced technologies to reduce consumption. For this reason, companies should prioritize energy efficiency ratings and long-term operating data over short-term purchase savings.

Maintenance and Spare Parts Costs

A thermal shock test chamber is a complex system composed of compressors, circulation fans, heating elements, solenoid valves, temperature sensors, and other precision components. During continuous operation, wear and aging are unavoidable, making regular maintenance and part replacement necessary.

If the manufacturer’s after-sales support is weak, with long lead times or high prices for spare parts, companies may face unexpected costs and operational risks. In severe cases, a failure in a core component may require replacement of the entire assembly, with repair expenses approaching the cost of a new unit.

To avoid this, buyers should carefully evaluate the responsiveness of after-sales service, the transparency of spare part pricing, and the manufacturer’s ability to supply components promptly. Choosing a supplier with a well-established service network and standardized spare parts system can significantly reduce long-term maintenance expenses.

Installation and Facility Modification Costs

Thermal shock test chambers are large, heavy, and demanding on facility infrastructure. Several factors must be considered:

-

Load-bearing requirements: Large chambers can weigh several tons, often requiring floor reinforcement.

-

Electrical capacity: High-power chambers need three-phase power and a stable supply. Electrical system upgrades are a common additional expense.

-

Ventilation and heat dissipation: Chambers generate considerable heat during operation. If the laboratory lacks adequate ventilation or air conditioning, further modifications are necessary.

These hidden costs are often overlooked until installation, forcing unplanned spending and delays. To prevent such issues, companies should conduct a site survey and facility assessment before purchase, with a realistic budget set aside for modifications.

Downtime Costs

When a thermal shock test chamber fails or requires maintenance, testing schedules are immediately disrupted. For companies where R&D cycles define competitiveness, downtime losses often far outweigh the direct cost of repairs.

During downtime, product validation, quality assurance, and even customer deliveries may be delayed. In critical phases of new product development, equipment unavailability can result in missed market opportunities.

Therefore, buyers should evaluate not only performance specifications but also equipment reliability and proven stability. Choosing a low-failure, market-proven brand that provides rapid service response is the most effective way to minimize downtime costs.

Training and Operational Costs

As a high-end piece of laboratory equipment, a thermal shock test chamber requires skilled operators. Without adequate training, staff may misuse the chamber, leading to equipment damage, compromised data accuracy, or even safety incidents. Additionally, insufficiently trained operators are less likely to leverage the chamber’s full performance potential, reducing testing efficiency and reliability.

Some manufacturers provide comprehensive training programs upon delivery, covering operational protocols, daily inspections, and troubleshooting. This minimizes the risk of misuse, extends equipment lifespan, and enhances data accuracy. Conversely, if training is neglected, companies may need to invest additional manpower and time to compensate.

Conclusion

The hidden costs of thermal shock test chambers can be grouped into five categories: energy consumption, maintenance and spare parts, installation and facility modifications, downtime, and training and operations. Only by recognizing these factors in advance can companies properly plan budgets and make informed purchasing decisions.

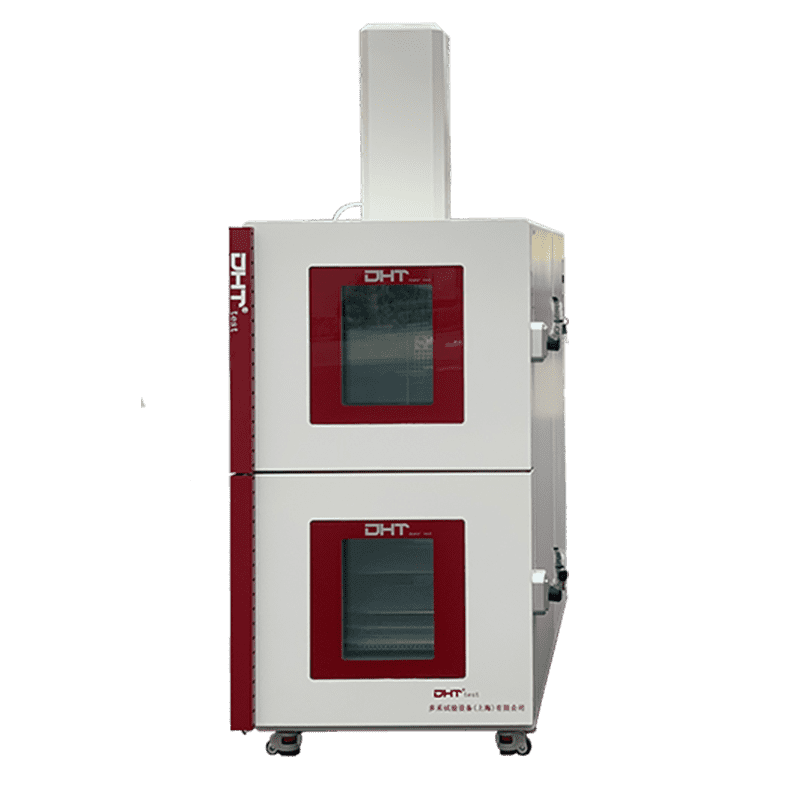

DHT® Thermal Shock Chambers offer a competitive edge by combining cutting-edge performance and energy-efficient design with robust after-sales service and professional training. With DHT®, enterprises can minimize long-term costs and maximize their return on investment.

Contact the DHT® team today for tailored technical consultation and customized solutions.