Purchasing a benchtop environmental chamber is a major investment. Comparing specifications and prices alone is not enough—asking the right questions will reveal the chamber’s true value, reliability, and long-term operating costs.

In this article, we’ll share six critical questions you should ask your supplier to help you make the smartest purchasing decision.

Technical Core & Performance Reality

-

Can you provide the exact testing conditions under which the listed specifications (e.g., temperature range of -70°C to +180°C) were achieved? For example, were these results obtained under no-load conditions, or with a defined thermal load?

-

Why this matters: Specifications are often measured under “ideal conditions” (no load). In real-world applications, your samples introduce thermal mass—and may even generate heat themselves. This question helps you understand the chamber’s actual performance limits. A responsible supplier should be transparent about achievable temperature ranges and ramp rates under specified loads.

-

Follow-up: “Can you share performance curves based on a standard load (e.g., XX kg aluminum block)?”

-

-

Was the stated temperature uniformity measured under no-load conditions, or can it be guaranteed under defined load conditions? What measurement standard was applied (e.g., what does ±0.5°C actually reference)?

-

Why this matters: Temperature uniformity is critical for test repeatability. Values measured in an empty small thermal chamber have limited meaning. You need to confirm whether uniformity is maintained with real samples in place and whether it meets your testing standards (ISO, MIL, etc.). This avoids inconsistent results caused by uneven temperature distribution.

-

Follow-up: “Was this uniformity verified according to ASTM E145, IEC 60068, or other international standards?”

-

Long-Term Cost & Reliability

-

What brands are used for the core components (e.g., compressor, controller, sensors)? Are alternative options available?

-

Why this matters: Core components are indicators of reliability. Well-known brands (e.g., Copeland compressors, Omron or Siemens controllers) usually ensure longer service life and stable performance. Understanding whether alternatives exist allows you to balance budget and performance.

-

Follow-up: “If a key component fails, what is the typical lead time for spare parts?”

-

-

Beyond the purchase price, can you provide a preventive maintenance plan and estimated annual operating costs (e.g., energy consumption)?

-

Why this matters: Total Cost of Ownership (TCO) is far more than the upfront price. A cheaper chamber may lead to high energy bills or frequent service costs. Asking this shows you are a savvy buyer who values long-term performance. It also helps you assess the supplier’s professionalism and transparency.

-

Follow-up: “What is the recommended calibration cycle, and how are calibration services priced?”

-

Software, Service & Future-Proofing

-

Does the control software include data logging functions? In what formats can data be exported (.csv, .txt)? Does it support remote monitoring?

-

Why this matters: In today’s data-driven environment, traceability and usability of test data are essential. You need to confirm that exported data can easily be integrated into your lab management systems. Remote monitoring can also improve efficiency by allowing you to track tests outside working hours.

-

Follow-up: “Is there an additional fee for software upgrades? Does the system support compliance requirements such as 21 CFR Part 11 (if applicable)?”

-

-

What exactly does the warranty cover? What is the typical on-site service response time? Do you provide application support (e.g., helping optimize my test programs)?

-

Why this matters: Warranty and service are your safety net after purchase. A clear policy (e.g., one-year warranty, three years on compressor) provides peace of mind. Defined response times are critical for avoiding delays in R&D or production. Application support also distinguishes a mere supplier from a true partner.

-

Follow-up: “In case of a malfunction, do you provide multi-level support (phone guidance, remote diagnostics, on-site engineers)?”

-

Conclusion

Asking these six questions is not just about gathering information—it’s a way to “stress-test” your supplier’s competence and professionalism. A trustworthy partner will treat these questions as an opportunity to showcase product strengths and service commitments, not as a burden.

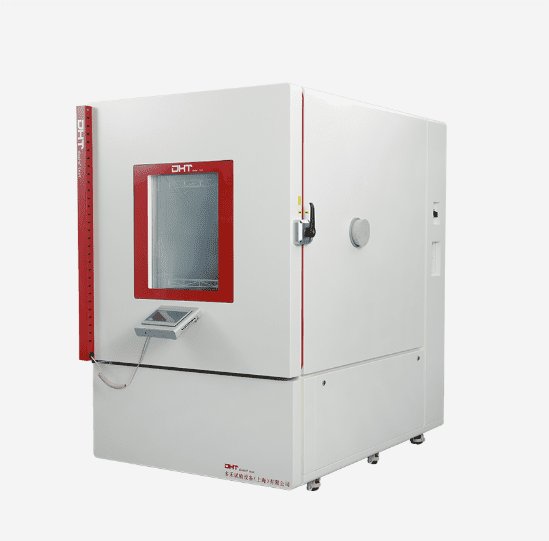

We encourage you to use this checklist to evaluate every potential supplier—including us at DHT®.

At DHT®, we believe transparency and professional support are the foundation of long-term partnerships. Our technical experts are always ready to answer these questions in detail and provide tailored benchtop environmental test chamber solutions, real performance data, and comprehensive service commitments.

Contact the DHT® team today for personalized technical consultation and free solution design.