Written by Robin

Senior Engineer, Doaho Test (DHT®)

Why Do Lithium Batteries Require Aerospace Transportation Safety Testing?

Lithium batteries, as the most widely used energy storage devices today, are favored for their high energy density, lightweight nature, and long cycle life. They have become the core power source in aerospace, electric vehicles, satellite communications, and unmanned aerial vehicles. However, lithium batteries are also highly sensitive to environmental conditions.

During aerospace transportation, batteries must endure low-pressure conditions and extreme temperature variations that are completely different from ground-level environments. If there are flaws in battery design, packaging, or battery management systems, serious safety risks may arise under high-altitude or vacuum conditions.

Such risks include casing expansion, electrolyte leakage, combustion, or even thermal runaway. Therefore, international transportation standards impose stringent requirements on lithium battery aerospace transport. For example, the United Nations UN38.3 Dangerous Goods Transportation Test explicitly requires all lithium batteries to undergo low-pressure simulation testing prior to transportation. This ensures that batteries remain safe at a pressure of 11.6 kPa (equivalent to an altitude of approximately 15,000 meters). These standards are designed to ensure that even under extreme conditions, batteries will not leak, explode, or ignite, thereby protecting spacecraft and personnel safety.

The Importance of Altitude Test Chambers

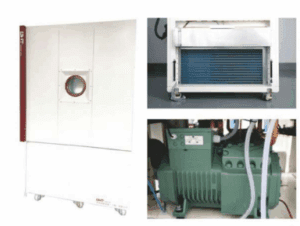

Among environmental testing equipment, the low-pressure test chamber (also known as an altitude chamber) is a critical instrument designed specifically to simulate high-altitude, low-pressure environments. It allows researchers and manufacturers to accurately reproduce the pressure conditions that batteries face during high-altitude flight, space transportation, or plateau operations—all within a laboratory setting. This helps detect potential defects before the product leaves the factory.

For lithium batteries, such testing is not only a compliance requirement but also a crucial safeguard for mission safety. By using a low-pressure test chamber, manufacturers can prevent battery-related accidents, reduce transportation risks, and collect valuable data for design optimization and safety improvements.

How Is Low-Pressure Testing for Lithium Batteries Conducted?

Low-pressure testing of lithium batteries is a systematic and rigorous process, typically carried out in the following steps:

- Sample Preparation: Prepare the battery or battery pack in accordance with the charge or discharge state specified by UN38.3, ensuring it meets the required state of charge (SOC) for testing.

- Placement in the Altitude Test Chamber: Secure the battery inside the chamber to prevent unnecessary movement or mechanical stress during vacuum pumping and pressure reduction.

- Pressure Reduction: Activate the vacuum system to gradually lower the chamber pressure to 11.6 kPa, simulating high-altitude or aerospace conditions.

- Pressure Holding Stage: Maintain the target pressure for at least 6 hours while monitoring the battery’s appearance, dimensions, and casing integrity, recording any leakage, swelling, rupture, or combustion.

- Return to Atmospheric Pressure and Inspection: Slowly restore the chamber pressure to normal atmospheric conditions, then perform comprehensive inspections of the battery, including voltage, capacity, and appearance, to ensure no abnormalities are present.

Common Testing Items

In addition to low-pressure simulation, aerospace transportation safety evaluation for lithium batteries generally involves multiple environmental stress tests, including:

- Low-Pressure Test: Simulates atmospheric pressure changes at high altitudes or in near-space environments to assess sealing, casing stability, and overall safety.

- Vibration and Shock Test: Simulates bumps, impacts, and acceleration shocks during transport to ensure structural integrity and connection reliability.

- Temperature Test: Subjects batteries to high/low temperature cycles or constant extreme temperatures to evaluate performance and stability under thermal stress.

- Humidity Test: Exposes batteries to high-humidity environments to assess insulation, casing durability, and risks of corrosion or leakage.

- Other Specialized Tests: Depending on mission requirements, additional tests such as salt spray, drop tests, and charge–discharge cycling may be conducted to cover the full range of risks during the aerospace transportation lifecycle.

This comprehensive and stringent testing process ensures that lithium batteries can maintain stable and safe operation even under low-pressure, strong vibration, and extreme temperature and humidity conditions. It provides solid assurance for both aerospace transportation and in-orbit applications.

Specifications

| DHT® Altitude Temperature Test Chamber | ||||

| Temperature Model | Model | DHTA-5OO | DHTA-O1O | DHTA-O15 |

| Climatic Model | Model | DHTHA-5OO | DHTHA-O10 | DHTHA-O15 |

| Working Room volume | L | 500 | 1000 | 1500 |

| Temperature Test Data | ||||

| Temperature Range | ℃ | 0(-20,-40,-70)/180 | ||

| Heating Rate | ℃/min | 2.O~4.O | ||

| Cooling Rate | ℃/min | O.7~3.5 | ||

| Temperature Fluctuation | ℃ | ±O.5 | ||

| Temperature Uniformity | ℃ | 2 | ||

| Temperature&Humidity Test Data | ||||

| Temperature Range With Humidity | ℃ | 15~95 | ||

| Humidity Range | %RH | 2O~98% | ||

| Humidity Fulctuation | %RH | ±1.O~±3.O | ||

| Pressure Range | kPa | Normal pressure~O.5kPa | ||

| Pressure Deviation | kPa | ≥40h:±2 2~40h:±5% ≤2h:±0.1 | ||

| Pressure Change Rate | kPa/min | ≤10 | ||

| Internal Dimensions | W(mm) | 800 | 1000 | 1100 |

| D(mm) | 700 | 1000 | 1475 | |

| H(mm) | 900 | 1000 | 950 | |

| External Dimensions | W(mm) | 1090 | 1290 | 1390 |

| D(mm) | 1470 | 1780 | 2680 | |

| H(mm) | 1890 | 2030 | 1995 | |

| Standards | GB/T11159-2010、GB/T10590-2006、GB/T 10591-2006、GB/T 10592-2008、GB/T 2423.25-2008、GB/T2423.26-2008、GB/T 2423.1、GB/T2423.2、GB/T 2423.21、GJB150.3、GJB150.4.GJB150.2(Except for rapid blood pressure reduction)、GJB150.19、GJB150.24A… | |||

| Power Voltage | 380V±10%,50~60HZ,3/N/PE | |||

| Sound Pressure Level | dB(A) | 70 | 70 | 70 |

| Cooling Mode | Air Cooling/Water Cooling | |||

Conclusion

As a critical instrument for simulating high-altitude and vacuum environments, the Altitude Test Chamber provides robust technical support for lithium battery safety validation. Through precise pressure control and long-duration, reliable testing, manufacturers can identify potential risks before products leave the factory, thereby reducing transportation hazards. Leveraging its advanced technology and extensive industry expertise, DHT® will continue to deliver high-quality environmental testing solutions, supporting the lithium battery industry in achieving steady progress in both safety and innovation.