- HOME

- INDUSTRIESReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- AerospaceReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- AutomotiveReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- BatteryReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- BiotechnologyReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- ChemistryReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- DefenseReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- ElectronicsReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- EnergyReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- MaterialReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

- TelecommunicationsReliability & Safety Testing are both paramount for the automotive market, whether it is keeping drivers & passengers safe or decreasing warranty cost from expensive recalls. Environmental tes…

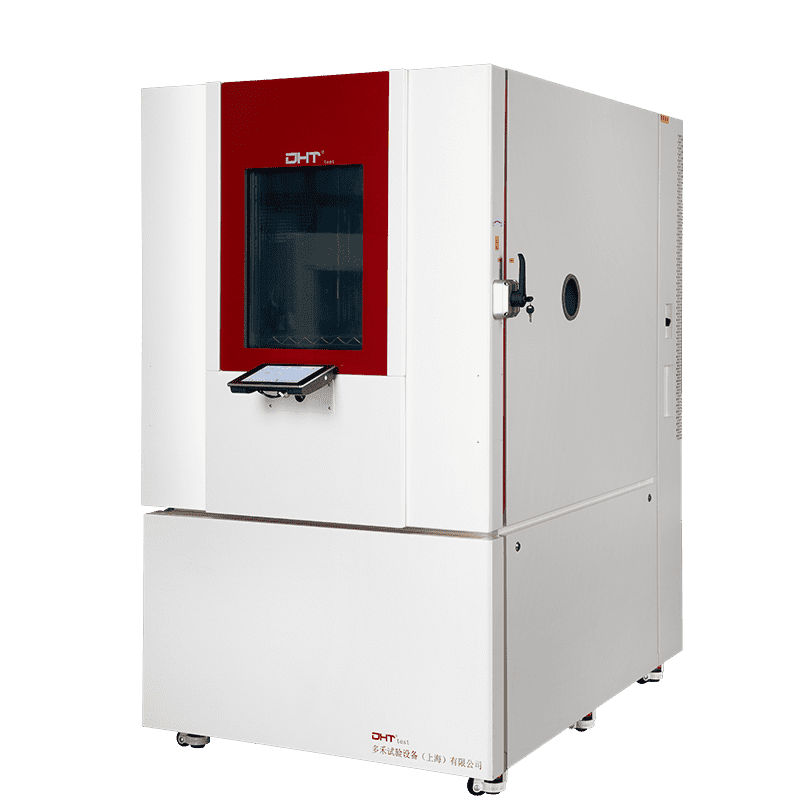

- PRODUCTShermotron builds environmental test equipment to test the limits of our clients’ products. We make unique chambers to test temperature, humidity, altitude, and vibration. Our chambers and shakers test…

- COMPANY

- NEWS

- CUSTOMER SUPPORT

-

Maintenance Support

Experienced engineers with specialized tools provide fast, accurate repairs for all test chambers.

Custom Development

One-stop service from design to testing, with flexible function module options.

Global Logistics

Door-to-door delivery worldwide with shockproof, moisture-proof, and anti-rust packaging.

Technical Support

24/7 online help. Most issues solved remotely.

Chamber Leasing

Daily, monthly, or quarterly rental plans to save costs and meet short-term needs.

User Community

Share your experience and testing stories on YouTube, Facebook, or in industry groups.

Schedule Service

DHT® offers a range of high-quality precision test chambers, along with excellent after-sales service. If you have any needs, please contact us.

-

- CONTACT

试验箱-2.png.webp)

试验箱-1.png.webp)

试验箱.png.webp)