Geschrieben von Robin

Leitender Ingenieur, Doaho Test (DHT®)

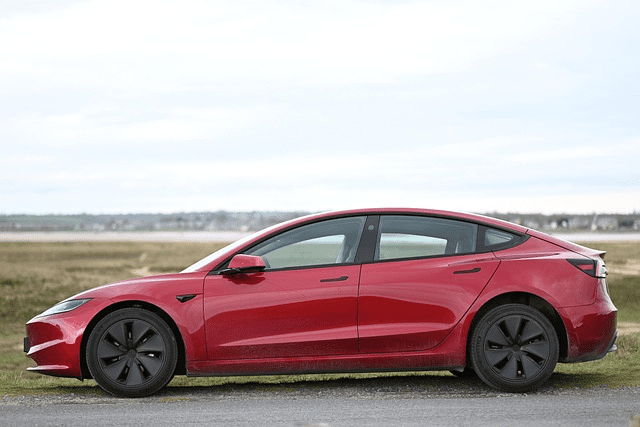

On icy winter roads, a car’s undercarriage silently endures saltwater splashes and moisture exposure; in humid coastal cities, body metal components face constant exposure to salty air. Such real-world conditions make corrosion resistance a critical focus for automotive component R&D and quality control. By conducting precise corrosion testing in a corrosion test chamber, engineers can simulate these extreme environments in the laboratory, identifying potential weaknesses in materials and coatings ahead of time. This approach not only prevents early vehicle damage and reduces after-sales risk but also provides scientific guidance for process improvements, ensuring every vehicle leaves the factory with enhanced durability and safety.

This article presents practical case studies and applications of corrosion test chambers, offering actionable testing and maintenance strategies for the automotive component industry.

Importance of Corrosion Testing

Corrosion testing evaluates a material or component’s durability and resistance to corrosive factors such as salt spray, humidity cycles, acid rain, or chemical agents. Automotive components are often exposed to high humidity, salt, acid rain, road salts, and temperature fluctuations during their service life. These factors can cause metal oxidation, coating failure, and loosening of fasteners, potentially compromising overall vehicle safety.

The core objectives of corrosion testing include:

- Identifying design flaws in materials or coatings.

- Optimizing anti-corrosion processes and material selection.

- Providing reliable quality verification reports for certification and customer acceptance.

Case Study 1: Engine Compartment Metal Bracket Salt Spray Test

During the development of a new engine bracket, an automaker performed a salt spray corrosion test in a corrosion test chamber. Test conditions were set at 35°C, 5% NaCl concentration, over 480 hours.

Results:

- The zinc coating on the bracket surface began to flake locally after 360 hours.

- Slight rust appeared on bolt joints, but no significant structural deformation occurred.

Based on the data, the R&D team increased the zinc plating thickness and added a corrosion-resistant coating to the bolts. Re-tested samples showed no significant corrosion under the same conditions, meeting the design standards.

Key takeaway: Salt spray testing allows manufacturers to identify material and process weaknesses before mass production, avoiding large-scale rework and after-sales issues.

Case Study 2: Exterior Body Trim Humid Heat Cycle Test

Exterior trim components are frequently exposed to rain, humidity, and high temperatures. A supplier of chrome-plated decorative parts designed a humid heat cycle corrosion test in a corrosion test chamber with the following cycle:

- High-temperature humidity: 60°C, 95% RH for 12 hours.

- Room temperature drying: 25°C, 50% RH for 12 hours.

- Cycle repeated for 30 days.

During the test, some chrome-plated parts developed minor water spots and slight blistering, indicating localized coating failure under high humidity. The supplier optimized the plating process and applied additional sealing coatings on critical areas. The improved parts demonstrated stable performance in repeated cycles and passed customer acceptance.

Key takeaway: Humid heat cycle testing simulates long-term exposure to variable climates, providing direct data for process optimization.

Case Study 3: Brake System Metal Parts Salt Spray and Humid Heat Combined Test

Brake systems involve safety-critical components, making corrosion resistance essential. A car manufacturer conducted a combined corrosion test on calipers and discs, integrating salt spray and humid heat cycles for 1,000 hours.

Findings:

- Low-alloy steel calipers showed rust spots after 700 hours.

- Steel mounting bolts exhibited slight oxidation during humidity cycles, but thread integrity remained intact.

The team upgraded the material to high-corrosion-resistant alloy steel and applied zinc plating with anti-rust oil on the bolts. Re-testing showed no corrosion, confirming the effectiveness of material improvements.

Key takeaway: Combined corrosion testing provides a more comprehensive evaluation for complex and safety-critical components, minimizing risks overlooked by single tests.

Practical Recommendations for Using Corrosion Test Chambers

Based on these case studies, automotive component manufacturers can optimize corrosion testing by focusing on:

- Defining test objectives and conditions: Match the salt spray type, humidity/temperature cycles, and duration to the component’s material, usage environment, and customer requirements to ensure realistic results.

- Maintaining chamber accuracy and stability: Regularly calibrate temperature and humidity sensors, and clean spray systems and piping to prevent deviations in test data.

- Establishing complete data records: Track sample performance and anomalies for trend analysis, identifying weak points in materials or coatings to guide process improvement.

- Risk-prioritized testing: Increase test frequency for critical or high-risk parts while extending intervals for non-critical components, optimizing resources and ensuring comprehensive coverage for key data.

Schlussfolgerung

Case-driven corrosion testing enables automotive component manufacturers to uncover potential material or process issues, optimize design, extend product life, and enhance overall vehicle reliability. Scientific application of corrosion testing and corrosion test chambers establishes a closed loop between R&D, production, and quality management, delivering measurable risk control and economic benefits.

For companies seeking higher testing accuracy, extended chamber lifespan, or tailored corrosion testing solutions for specific components, the DHT® Technical Team can provide customized support. With years of industry experience and engineering expertise, DHT® ensures every test is more efficient, reliable, and fully traceable.

Häufig gestellte Fragen

Was ist Korrosionsprüfung und warum ist sie für Automobilkomponenten wichtig?

Korrosionstests bewerten die Haltbarkeit und Beständigkeit von Automobilmaterialien und -komponenten gegenüber Faktoren wie Salzsprühtests, Feuchtigkeitszyklen, saurem Regen und chemischen Mitteln. Sie helfen dabei, potenzielle Schwächen in Materialien oder Beschichtungen zu identifizieren, Korrosionsschutzprozesse zu optimieren und sicherzustellen, dass Komponenten Qualitätsstandards erfüllen, um letztendlich die Sicherheit und Zuverlässigkeit von Fahrzeugen zu erhöhen.

Wie helfen Korrosionsprüfkammern bei der Prüfung von Automobilkomponenten?

Korrosionsprüfkammern simulieren extreme reale Bedingungen, wie z.B. salzige Straßen oder feuchte Küstenumgebungen, und ermöglichen es Ingenieuren, Metallhalterungen, Karosserieteile und Bremsbauteile unter kontrollierten Salzsprüh- und Feuchtigkeits-/Temperaturzyklen zu testen. Dies ermöglicht die frühzeitige Erkennung von Material- oder Beschichtungsschwächen und unterstützt Prozessverbesserungen vor der Massenproduktion.

Welche Best Practices sollten Hersteller befolgen, wenn sie Korrosionstestkammern verwenden?

Hersteller sollten Testziele basierend auf Materialtyp und Nutzungsbedingungen definieren, die Kammergenauigkeit durch regelmäßige Kalibrierung und Reinigung aufrechterhalten, Testdaten für Trends aufzeichnen und analysieren sowie risikopriorisierte Tests implementieren, indem sie sich mehr auf kritische oder hochriskante Komponenten konzentrieren. Diese Praktiken optimieren die Ressourcen und gewährleisten zuverlässige, nachvollziehbare Korrosionstestergebnisse.