Geschrieben von Robin

Leitender Ingenieur, Doaho-Test (DHT®))

Amid the global wave of intelligent manufacturing upgrades, environmental reliability testing is undergoing revolutionary advancements. From validating extreme operating conditions for lithium battery packs in new energy vehicles to simulating space environments for satellite payloads; from sterile testing in biopharmaceutical cleanrooms to thermal management challenges for 5G base station chips—modern industrial products face unprecedented demands for quality validation. As the “precision ruler” in environmental reliability testing, high-performance test chambers must not only simulate extreme climates ranging from polar cold to desert heat but also accurately replicate complex conditions like high-speed vibration and vacuum microgravity. These top-tier safety-certified chambers serve as the first line of defense for quality assurance in advanced manufacturing.

In this precision-driven technological race, DHT® environmental test chambers act as rigorous “product health inspectors.” Leveraging their TÜV Rheinland-certified safety architecture, they redefine traditional testing boundaries and have become a trusted brand for enterprises worldwide. This article delves into how these Europe-inspired, German-quality test chambers deliver comprehensive environmental adaptability and durability validation, building a full-chain quality “moat” from R&D to mass production.

Ich.Environmental Testing: The “Extreme Proving Ground” of Modern Manufacturing

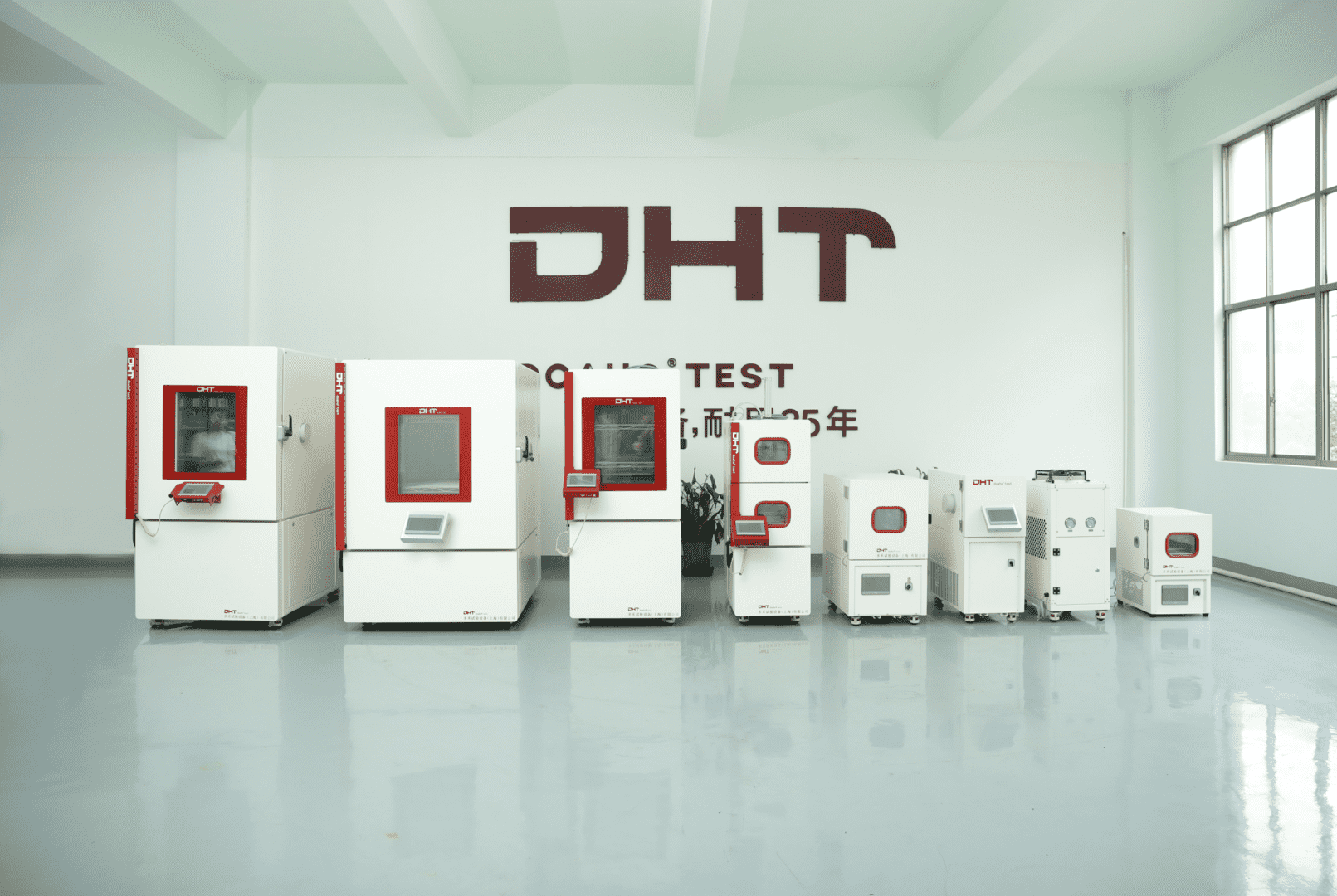

As EV batteries endure 70°C desert heat and satellite components withstand -270°C space vacuums, environmental test equipment has become the “ultimate simulator” of industrial civilization. Such equipment must not only replicate temperature shifts from the Arctic Circle to the equator but also achieve rapid temperature transition rates akin to typhoon-level intensity. To ensure product stability under extreme conditions, enterprises increasingly rely on high-precision, ultra-stable test chambers. For example, the DHT® thermal shock test chamber achieves a “temperature rollercoaster” transition from -65°C to +180°C in just 5 minutes, setting the benchmark for evaluating 5G chip thermal performance. Meanwhile, DHT® walk-in test chambers, with their large-scale, isolated environments, provide robust support for full-vehicle and bulk product testing. DHT® continues to innovate in test chamber technology, solidifying its leadership in the industry.

II.DHT® Labs: Die Neudefinition thermodynamischer Grenzen

1. Präzisions-Temperaturregelung und Energie-Effizienz

DHT® temperature and humidity chambers employ a dual-loop intelligent control system, achieving ±0.1°C temperature accuracy and ±1% RH humidity stability. This precision not only meets ISO 17025 laboratory standards but also answers the critical question: “How to select a reliable environmental test chamber?” Their zonal energy recovery system reduces energy consumption by 30%, fulfilling the promise of cost-effective climate test chamber manufacturers.

2. schnelle Reaktion und extreme Leistung

Bei der Entwicklung einer Hochleistungstestkammer für Luft- und Raumfahrtanwendungen hat DHT® ein dreistufiges Kaskadenkühlsystem für Hoch-Tief-Temperatur-Schockkammern entwickelt. Diese Kammern erfüllen die DO-160G-Avionikstandards mit ultraschnellen Übergängen zwischen extremen Temperaturen und haben erfolgreich 2.000 einwandfreie thermische Zyklen in Satelliten-Nutzlast-Validierungsprojekten absolviert.

3. begehbare Kammern: Maßstab trifft auf Präzision

Die begehbaren DHT®-Kammern verfügen über modulare Designs, die durch CFD-Luftstromsimulationen optimiert wurden und eine Gleichmäßigkeit von ±1°C in 8m³ großen Räumen erreichen. Mit doppelt abgedichteten Türen und redundanten Kühleinheiten sind sie die beste Lösung für die Prüfung von Energieanlagen. Die strenge Validierung von Isolierung, Druckbeständigkeit und Abdichtung gewährleistet sowohl Stabilität als auch Sicherheit.

III. Wettbewerbsvorteil: DHT® im Vergleich zu Branchenkollegen

1. führend in Innovation und F&E

Im Bereich der Salzsprühnebeltests leistete DHT® Pionierarbeit mit einem zyklischen Trocken-Nass-Korrosionssystem, das die herkömmlichen Sprühmodi zur Simulation von Meeres-, Industrie- und verschmutzten Umgebungen verbessert. Seine intelligente Düsenanordnung erreicht eine Effizienz von 96% bei der Salzabscheidung, erhöht die Testgeschwindigkeit um 5% und ist führend bei der Einhaltung der IEC 60068-2-52.

2. nutzerzentriertes Design

DHT® integriert fortschrittliche Touchscreens, Fernüberwachung und KI-gesteuerte Fehlervorhersage und minimiert so Betriebsfehler. Wettbewerber hinken bei intelligenten Schnittstellen hinterher und haben Schwierigkeiten, die Anforderungen moderner Produktionslinien zu erfüllen.

3. lebensbegleitende Unterstützung & Service Excellence

Das von Experten geleitete Serviceteam von DHT® bietet End-to-End-Support für Installation, Wartung und Upgrades. Konkurrenten bieten zwar Qualitätshardware an, sind aber oft unzureichend in Bezug auf Reaktionszeiten, maßgeschneiderte Lösungen und globale Serviceabdeckung - Schlüsselfaktoren für die überragende Kundenzufriedenheit von DHT®.

IV.Kundenspezifische Lösungen: Ein strategisches Unterscheidungsmerkmal

For EV battery testing, DHT® developed explosion-proof test chambers with hydrogen monitoring and active ventilation to meet UN38.3 standards. For defense needs, military-grade “three-proof” chambers (salt fog/humidity/mold) use titanium spray towers and antimicrobial coatings to achieve GJB150A-2009 compliance cost-effectively. Such tailored innovations position DHT® as a cross-industry leader in aerospace, automotive, and defense.

V.Schlussfolgerung

In der Ära von Industrie 4.0, in der Qualitätsstandards eine Präzision im Mikrometerbereich erreichen, definiert DHT® die Maßstäbe für Umwelttests durch bahnbrechende thermodynamische Innovationen neu. Von Laboren bis zu Produktionslinien, von terrestrischen Systemen bis zu Nutzlasten im Weltraum - DHT®-Prüfkammern schaffen ein neues Paradigma in der Zuverlässigkeitstechnik und sichern den industriellen Fortschritt der Menschheit mit beispielloser thermischer Beherrschung.