Geschrieben von Robin

Leitender Ingenieur, Doaho Test (DHT®)

Salzsprühnebeltest Chambers: The Invisible Guardian of Product Quality

In today’s fiercely competitive market, product quality is no longer a “nice-to-have” bonus—it’s a vital cornerstone of building customer trust and brand credibility. Among the various tools for ensuring quality and reliability, the Salzsprühnebel-Testkammer stands out as one of the most widely used devices for environmental corrosion testing. It plays a critical role in evaluating corrosion resistance and ensuring consistent product quality before it reaches the market.

From automotive parts and electronic connectors to metal surface treatments and medical devices, the ability of a product to withstand salt spray exposure can directly impact its failure rate and customer satisfaction. However, salt spray test chambers are far from one-size-fits-all. Different applications and testing objectives require distinct models, configurations, and performance parameters.

So how can a company choose a chamber that truly fits its product needs? In this article, we’ll walk you through everything from testing goals and key performance metrics to industry-specific selection logic—helping you avoid costly missteps and make a smarter, higher-ROI investment.

Start with the “Why”: Understanding Your Testing Objective

Before getting into brand names or price points, the first—and most critical—question to ask is: What are you trying to test? The answer will determine the type of chamber, its technical specifications, and its functional configuration.

-

Corrosion resistance of metal components: For parts like screws, zinc-aluminum castings, or automotive plating, Neutral Salt Spray (NSS) or Copper Accelerated Acetic Acid Salt Spray (CASS) tests are commonly used. Make sure the chamber complies with international standards such as ASTM B117 or ISO 9227.

-

Adhesion and durability of coatings: If you’re working with painted surfaces, powder coatings, or anodized films, the focus is on how well these coatings resist bubbling, peeling, and corrosion under high humidity and salt-laden environments.

-

Eindringen protection of electrical equipment: For outdoor enclosures and junction boxes, salt spray testing verifies IP ratings by assessing sealing and corrosion resistance under harsh conditions.

-

Cyclic corrosion testing (CCT): If your test involves multiple environmental phases—such as thermal shock, salt exposure, and drying—you’ll need a cyclic or dual-chamber test system capable of simulating real-world fluctuations.

In short, your test materials, corrosive agents, cycle duration, and testing frequency will directly influence the chamber model and configuration. Defining your test objective is the first and most important step in scientific selection—and the key to avoiding wasted investment.

Key Technical Parameters: Where Performance Makes the Difference

1. Temperature Control Capability

-

Operating range: Standard NSS tests require 35°C; CASS requires 50°C. For more advanced tests, opt for models with a wider range (e.g. 20°C–70°C).

-

Temperature uniformity: ≤±2°C across the chamber to ensure consistent corrosion rates across all samples.

-

Temperature fluctuation: ≤±0.5°C to prevent salt crystallization, which can block spray nozzles.

2. Salt Fog Deposition Rate

-

Standard requirement: 1.5 ± 0.5 ml/80cm²·h, as specified by ASTM B117. Insufficient fog weakens the test; excessive fog can cause false failures.

-

Recommended solution: A tower-type spray system with quartz nozzles provides more consistent atomization and 60% higher stability compared to traditional centrifugal systems.

3. Sealing and Corrosion Kompatibilität

-

Chamber liner: Choose PVC, PP, or FRP materials with high corrosion resistance for long-term use.

-

Door seals: Use EPDM or corrosion-resistant silicone gaskets to ensure zero leakage during testing.

-

Sample racks: High-end models offer titanium or stainless steel racks, which outperform plastic structures in both strength and durability—lasting up to 2–3 times longer.

4. Spray Method and Distribution Uniformity

-

Use tower-type or precision nozzle spray systems to ensure continuous atomization and uniform fog distribution.

-

High spray uniformity is essential for consistent corrosion performance across different samples, especially in batch testing scenarios.

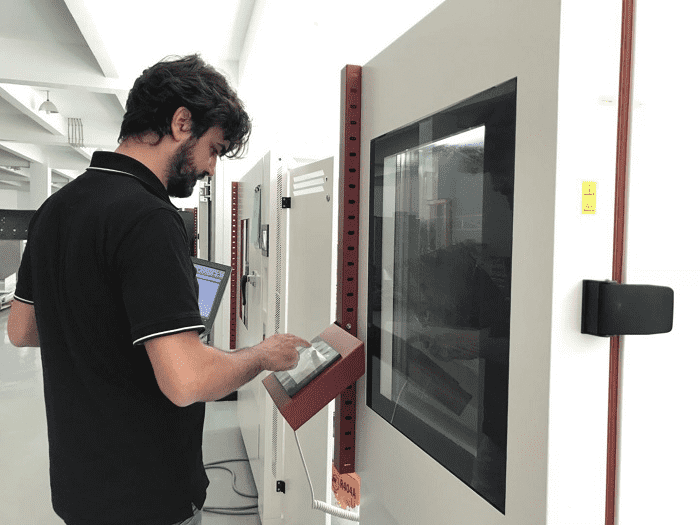

5. Intelligentes Kontrollsystem

-

Robust PLC or touchscreen controller

-

Auto-refill system to support long-duration, unattended testing

-

Real-time monitoring and alarm for pH and deposition levels

-

Data export (USB/Ethernet), optional remote diagnostics & control

-

Multilingual interface with user access management

6. Chamber Volume and Load Capacity

General rule: Samples should not exceed 2/3 of the chamber’s internal volume, to maintain airflow and uniform fog dispersion.

Typical size reference:

-

Small parts: 90–270L (e.g., hardware, connectors)

-

Medium parts: 480–780L (e.g., lighting fixtures, panels)

-

Large parts/batch testing: 1000L+ (e.g., wheel rims, full assemblies)

Common Pitfalls in Chamber Selection: Are You Falling for These?

During the selection process, many companies fall into seemingly logical—but ultimately misleading—traps that result in misaligned equipment and increased operational risk. Here are the most common ones:

-

Assuming “all salt spray chambers are the same” Similar appearance ≠ equivalent performance. Critical differences in spray method, temperature control, and fog uniformity directly impact the repeatability and validity of your test results.

-

Ignoring upgrade potential in the control system You might only need basic functions now, but future testing may require multi-step programming, remote access, or data export. Without room for expansion, you’ll face a costly full replacement later.

-

Choosing “the biggest model” instead of the right size Oversized chambers waste energy and reduce fog uniformity when testing small batches. The 2/3 volume rule ensures optimal performance and efficiency.

-

Overlooking total lifecycle costs Low-priced units may save on upfront costs but often suffer from stability issues, short component life (e.g. nozzles, gaskets), and frequent maintenance—driving up long-term operating costs.

-

Neglecting user experience and operational convenience Lack of auto-refill, poor exhaust design, or missing cleaning ports can cause workflow interruptions. A clear, intuitive interface also significantly improves efficiency.

- Blindly chasing premium brands without considering fit and ROI Global brands may offer cutting-edge tech, but they’re not always the best choice for every use case. For small-scale R&D or prototyping, such systems might be over-engineered and slow to customize. Instead, consider brands with proven technology, flexible configuration, and responsive local support—they often deliver better practical value.

Recommended Brands: Make Smart Choices Based on Your Budget and Needs

| Brands | Target Users | Key Features |

| Espec | High-end research institutions, multinational corporations | Exceptional stability with modular customization options |

| Thermotron | Aerospace and high-reliability testing sectors | Highly integrated design supporting multi-condition (combined) testing |

| Weiss Technik | German industrial clients | Outstanding safety and superior test precision |

| Bindemittel | Pharmaceutical and medical industries | User-friendly operation with comprehensive data traceability |

| DHT®. | Mid-to-high-end industrial R&D and cost-performance-focused customers | In-house developed control system, customizable and easy to maintain — ideal for long-term, high-frequency testing scenarios |

Smart Selection for Long-Term Quality – Powering Your Product’s Future

A Der inhärent raue und korrosive Testumgebungen bedeutet jedoch, dass die Salznebelprüfkammer ständig 'unter Stress' ist. Ohne ordnungsgemäße tägliche Wartung kann sie unter ungleichmäßiger Sprayverteilung, Systemverstopfungen, Temperaturregelungsfehlern und Dichtungsverschlechterung leiden – allesamt Faktoren, die zu ungenauen Ergebnissen oder sogar zu vorzeitigem Ausfall der Ausrüstung führen können. Im Gegensatz dazu kann ein systematisches Wartungsprogramm die Lebensdauer der Kammer erheblich verlängern, Ausfallzeiten reduzieren und die Betriebseffizienz verbessern. isn’t just a one-time equipment purchase — it’s a vital gear in your company’s quality assurance engine. Choosing the right chamber enables you to identify potential failures early, shorten development cycles, reduce after-sales risks, and ultimately gain a competitive edge in today’s demanding market.

If you’re unsure about which model fits your needs, or if you want a tailored technical assessment based on your product, the DHT®-Team is here to help. We offer expert selection guidance and customized solutions to support your product’s journey — further, and with greater reliability.