Geschrieben von Robin

Sand and dust testing plays a crucial role in validating a product’s adaptability to harsh environmental conditions. It simulates the effects of natural elements such as wind-blown sand and dust on products, primarily to evaluate their dust protection and structural sealing capabilities. This type of testing is widely applied in the automotive, defense, telecommunications, electrical, and electronics industries.

Da die Erwartungen an die Produktqualität und -zuverlässigkeit weiter steigen, legen die Hersteller immer mehr Wert auf die technische Leistung, Stabilität und Eignung von Sand- und Staubblasprüfkammern.

Dieser Artikel untersucht fünf Schlüsselfaktoren - Testanforderungen, technische Spezifikationen, Steuerungssysteme, Gerätesicherheit und Markenservice -, um Ihnen bei der informierten Auswahl des idealen

Sandstaubprüfkammerzu helfen. Wir stellen auch eine vertrauenswürdige Markenlösung vor, die in Betracht gezogen werden sollte.

Definieren Sie Testanforderungen: Beginnen Sie mit den Schutzarten

Der erste Schritt bei der Auswahl einer geeigneten Kammer ist die Bestimmung des erforderlichen Schutzgrades. Die Prüfung von Sand und Staub erfolgt in der Regel nach den IP-Klassifizierungen (Ingress Protection) gemäß IEC 60529. Zwei Hauptklassifizierungen sind besonders relevant:

-

IP5X: Bietet Schutz gegen das Eindringen einer schädlichen Menge an Staub, obwohl ein gewisser Anteil an Staub dennoch eindringen kann, ohne den normalen Betrieb zu beeinträchtigen.

-

IP6X: Bietet vollständigen Schutz gegen das Eindringen von Staub und erfordert höhere Dichtungsstandards.

Verschiedene Anwendungsszenarien erfordern unterschiedliche Schutzniveaus. So erfordern beispielsweise Kommunikationsgeräte für den Außenbereich und Militärelektronik häufig die Einhaltung der Schutzart IP6X, während Haushaltsgeräte und Module für den Automobilbereich mit der Schutzart IP5X ausreichend geprüft sein können. Wenn Sie Ihre Konformitätsziele und die erwartete Testhäufigkeit kennen, können Sie übermäßige Investitionen oder eine mangelhafte Validierung vermeiden.

Technische Schlüsselindikatoren: Luftstrom und Staubzirkulationssystem

Der Kern der Sand- und Staubprüfung liegt in der Steuerung des Luftstroms, der die Staubpartikel in einer abgedichteten Kammer über eine längere Prüfdauer befördert. Das Luftstromdesign der Kammer und das Staubzirkulationssystem wirken sich direkt auf die Prüfgenauigkeit und Wiederholbarkeit aus.

Zu den wichtigsten zu berücksichtigenden technischen Aspekten gehören:

-

Einstellbare Luftstromgeschwindigkeit: Typischerweise zwischen 1-3 m/s, um verschiedene Prüfnormen zu erfüllen.

-

Gleichmäßige Staubverteilung: Es wird sichergestellt, dass es keine lokal begrenzten hohen Konzentrationen oder "tote Zonen" gibt.

-

Kompatibilität mit mehreren Staubarten: Talkumpulver, Quarzsand oder trockene Erde, um unterschiedliche Prüfanforderungen zu erfüllen.

-

Unterdruck Kammerdesign: Verhindert das Austreten von Staub und schützt das Laborpersonal.

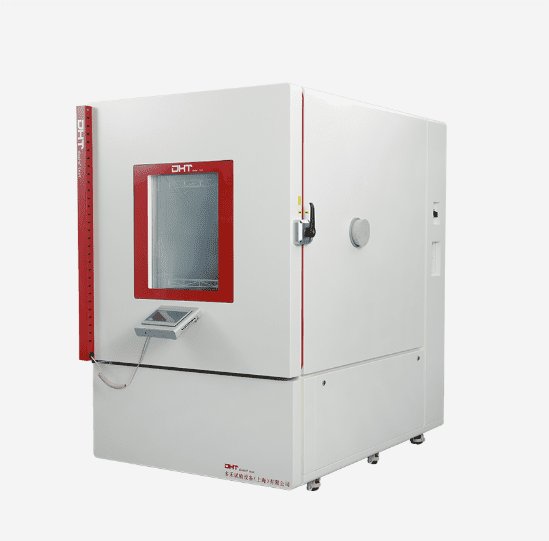

Beispielsweise verfügt die DHT® DHT-SD-Serie Sandstaubprüfkammer über ein vertikales Umluftdesign mit einem hochvolumigen, geräuscharmen Gebläsesystem. Dies gewährleistet eine gleichmäßige Staubverteilung und einen stabilen Luftstrom, vollständig konform mit den GB/T 4208 und IEC 60529 Standards und wird in der Branche hoch geschätzt.

Intelligentes Kontrollsystem: Gleichgewicht zwischen Effizienz und Benutzerfreundlichkeit

Ein zuverlässiges und effizientes Prüfverfahren erfordert ein fortschrittliches Steuerungssystem. Eine hochwertige Sandstaubprüfkammer sollte die folgenden intelligenten Merkmale aufweisen:

-

Touchscreen mit mehrsprachiger Benutzeroberfläche: Ermöglicht es Bedienern aus verschiedenen Regionen, das Gerät problemlos zu nutzen.

-

Programmierbare Prüfabläufe: Unterstützt zeitgesteuertes Staubblasen, Intervallzyklen und die Steuerung der gesamten Prüfdauer.

-

Echtzeit Überwachung und Datenexport: Erleichtert die Rückverfolgbarkeit und Berichterstattung.

-

Fernsteuerung und Alarmintegration: Erhöht die Sicherheit und reduziert die manuelle Überwachung.

DHT® zeichnet sich in diesem Bereich aus. Seine Kammern sind mit einem proprietären Steuersystem ausgestattet, das USB-Datenexport, LAN-Konnektivität und Ferndiagnose unterstützt. Optionale Videoüberwachungssysteme verbessern die Automatisierung und Sichtbarkeit weiter und machen das Labormanagement effizienter.

Strukturelle Integrität und Material Sicherheit: Langfristigen Betrieb gewährleisten

Sand- und Staubtests dauern oft mehrere Stunden oder sogar Tage, was hohe Anforderungen an die strukturelle Integrität und Materialbeständigkeit der Kammer stellt. Achten Sie bei der Auswahl auf die folgenden Merkmale:

-

Material der Innenkammer: SUS304-Edelstahl wird wegen seiner Korrosionsbeständigkeit und leichten Reinigung empfohlen.

-

Dichtungsleistung: Gute Dichtungen verhindern das Austreten von Staub und sorgen für eine sichere Laborumgebung.

-

Gestaltung der Beobachtungsfenster: Antistatische Folie und Beleuchtung erleichtern die Überwachung in Echtzeit.

-

Staubfiltration und Recycling-System: Verlängert die Lebensdauer der Geräte und senkt die Wartungskosten.

-

Antistatisch und Erdung Systeme: Vermeiden Sie die Entzündung von Staub oder Fehlfunktionen der Geräte.

Die DHT® Sandstaubkammern sind auf Sicherheit und Zuverlässigkeit ausgelegt und verfügen über ein vollständig geschlossenes Design, doppelte Türrahmendichtungen, automatische Staubentfernung und mehrere elektrische Schutzmechanismen. Diese Funktionen verringern das Ausfallrisiko und verlängern die Lebensdauer.

Marken- und Serviceunterstützung: Langfristiger Wert zählt

Die Investition in Umweltprüfgeräte ist eine langfristige Entscheidung. Die Partnerschaft mit einer Marke, die solides technisches Fachwissen und zuverlässigen Service bietet, gewährleistet eine maximale Investitionsrendite.

Mit jahrelanger Erfahrung in der Umweltprüfgeräteindustrie hat sich DHT® sowohl auf dem nationalen als auch auf dem internationalen Markt einen guten Ruf erworben. Gestützt auf solide F&E-Kapazitäten, ein umfassendes Produktportfolio und ein reaktionsschnelles Serviceteam bietet DHT® umfassende Unterstützung - von der Geräteauswahl und Installation bis hin zu Schulung und Kundendienst - und ermöglicht es den Kunden, zuverlässige und effiziente Testsysteme aufzubauen.

Schlussfolgerung: Intelligente Auswahl für mehr Produktzuverlässigkeit

Obwohl es sich bei der Sand- und Staubprüfung um eine Umweltprüfung mit nur einem Faktor handelt, lassen die strengen Normen und Leistungsanforderungen keinen Raum für Kompromisse. Wenn Sie Ihre Prüfanforderungen klar definieren, die technischen Parameter und Kontrollfunktionen bewerten und langfristigen Service und Support in Betracht ziehen, können Sie sich getrost für eine Sand-Staub-Prüfkammer entscheiden, die Ihren Produktvalidierungsanforderungen entspricht.

If you’re planning to invest in sand dust testing equipment, we invite you to

Kontaktieren Sie die DHT®-Experten für Umweltprüfungen. Unser Team ist bereit, maßgeschneiderte Empfehlungen und zuverlässige Lösungen zur Unterstützung Ihrer Produktqualitätsziele zu liefern.

Häufig gestellte Fragen

Welchen IP-Schutzgrad sollte ich für Sand- und Staubtests wählen?

The right IP level depends on your product’s application environment.

IP5X offers protection against harmful dust ingress and is suitable for general electronics and automotive modules.

IP6X ensures complete dust-tight sealing, ideal for critical equipment like military-grade electronics and outdoor communication devices.

Understanding your compliance goals helps avoid under- or over-specifying the test chamber.

Welche technischen Hauptfaktoren beeinflussen die Genauigkeit einer Sand- und Staubprüfkammer?

Accurate sand and dust testing relies heavily on the airflow system, dust circulation, and chamber sealing. Key indicators include:

Adjustable airflow velocity (typically 1–3 m/s)

Uniform dust distribution without dead zones

Compatibility with different dust types (e.g., talcum, silica, dry soil)

Negative pressure design to prevent dust leakage

These ensure reliable, repeatable test results in accordance with IEC 60529 and GB/T 4208.

Wie kann ich langfristige Zuverlässigkeit und Benutzerfreundlichkeit bei der Auswahl einer Staubprüfkammer sicherstellen?

Look for chambers with:

Durable SUS304 stainless steel inner lining

High-quality seals and anti-static windows

Intelligent touchscreen control with programmable cycles

Remote monitoring, USB data export, and built-in safety alarms

Also, choose a supplier that offers full lifecycle service—from installation and training to remote diagnostics and after-sales support. A strong brand like DHT® adds long-term value and peace of mind.