Geschrieben von Robin

Leitender Ingenieur, Doaho Test (DHT®)

Why Choose a Small Environmental Chamber?

As a vital tool for simulating external conditions such as temperature and humidity, environmental chambers have become a core configuration in many laboratories. However, not every laboratory requires or has the space to accommodate large-scale equipment. This is where small environmental chambers have gained increasing attention among researchers and procurement professionals.

How to Select a Compact Test Chamber?

Choosing the right Compact Test Chamber involves more than just comparing price or brand reputation. A thoughtful selection should consider the following aspects:

Define Testing Needs and Objectives

The first step in purchasing an environmental chamber is to clearly define your testing requirements. Different industries demand varying levels of performance. If your experimental goals are limited to basic temperature and humidity simulations, a small chamber will suffice. However, if your testing involves extreme temperature variations, long-term continuous operation, or specialized conditions, then a higher-performance small chamber—such as a compact thermal shock chamber—may be required.

Size and Space Constraints

The compact footprint of a small environmental chamber is one of its greatest advantages, making it ideal for laboratories with limited space. Still, size considerations are often more complex than they appear.

-

External dimensions: Ensure that the chamber can be moved through laboratory doors and corridors and positioned with adequate clearance for ventilation and heat dissipation.

-

Internal chamber size: While smaller units save space, overly compact chambers can limit airflow circulation, affecting temperature uniformity. If your test samples are larger or multiple specimens need to be tested simultaneously, select a chamber with an appropriately sized interior.

Performance and Parameter Matching

Despite their compact form, small environmental chambers must meet your testing specifications—this is critical to ensuring scientific validity. Key parameters include:

-

Temperaturbereich: Standard small chambers typically operate from -40°C to +150°C, with some high-performance models extending further.

-

Humidity range and accuracy: Crucial for tests involving moisture absorption or pharmaceutical stability studies.

-

Temperature uniformity and fluctuation: A vital factor for reproducibility. Large temperature differences across the chamber can distort test data.

-

Heating and cooling rates: Essential for applications requiring rapid thermal transitions, such as thermal shock tests.

When choosing performance parameters, align them with real testing needs rather than simply aiming for “higher is better.” Over-specification can drive up procurement and operating costs without offering practical benefits.

Control System and Level of Intelligence

As laboratories increasingly embrace digitalization, the intelligence level of environmental chambers has become a key consideration. Modern small chambers are often equipped with programmable control systems that allow users to predefine temperature and humidity profiles, reducing manual intervention.

Advanced features may include:

-

Remote monitoring and control: Researchers can track chamber status via PC or mobile devices, especially valuable for long-duration or unattended tests.

-

Data logging and export: Automatic recording of test data for convenient analysis, reporting, and compliance review.

-

Sicherheit mechanisms: Over-temperature alarms, power-failure protection, and automatic shutdown systems to prevent test interruptions.

For laboratories that value efficiency and data integrity, choosing a small chamber with intelligent functions can significantly improve long-term research productivity.

Reliability and Maintenance Costs

As precision instruments, small environmental chambers must deliver consistent stability while minimizing long-term maintenance costs. Pay attention to:

-

Core component quality: Chambers built with components from reputable manufacturers have lower failure rates and reduced service needs.

-

Supplier support: Reliable suppliers provide comprehensive after-sales service, spare parts availability, and professional technical assistance.

A common pitfall in procurement is prioritizing low upfront costs while overlooking long-term expenses. Chambers that are inexpensive at first but built with lower-quality parts or lacking dependable support often result in higher downtime, increased maintenance costs, and even delays in project progress.

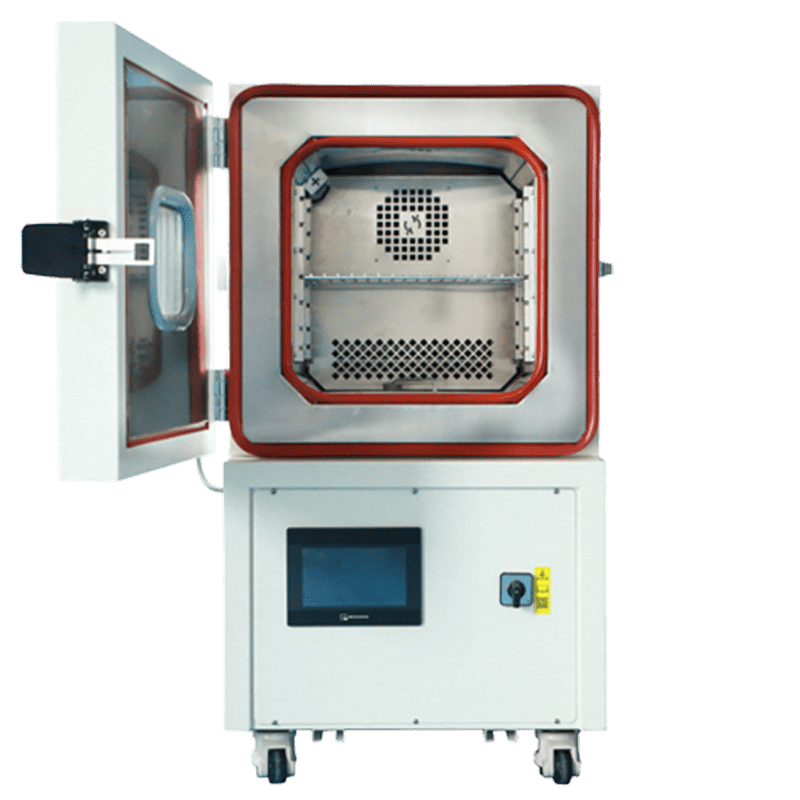

The Ideal Choice: DHT® Benchtop Temperature Chamber

As a manufacturer with years of expertise in environmental testing equipment, DHT® has established itself as a trusted provider of small environmental chambers. Combining stable performance, intelligent control systems, and exceptional cost-effectiveness, DHT® chambers are widely regarded as the preferred choice for laboratories and R&D facilities worldwide.

Key advantages include:

-

Precise temperature and humidity control: Achieving uniformity of ±0.5°C and fluctuation within ±0.5°C, with equally accurate humidity regulation. This is essential for experiments requiring highly repeatable and reliable results.

-

Wide operating range: Covering -70°C to +180°C, these chambers simulate conditions from extreme cold to high heat, meeting the needs of rigorous testing scenarios.

-

Benutzerfreundliche Schnittstelle: Featuring a full-color touchscreen interface with multi-segment programming support, simplifying complex test procedures.

-

Data management and remote monitoring: Standard USB data storage allows real-time recording and curve printing on PCs. Optional Ethernet/network modules enable remote monitoring and fault diagnostics, supporting modern laboratory digitalization.

-

Competitive acquisition cost: While compact in size and affordable in price, DHT® small environmental chambers do not compromise on performance. Offering the same quality, temperature range, and precision as leading international brands, DHT® provides these capabilities at a more reasonable cost—delivering a clear value advantage over expensive imported equipment.

-

Extensive service network: Headquartered in Shanghai with global reach, DHT® provides rapid-response service, ensuring engineers are always on call.

-

Professional technical support: A skilled technical team delivers expert guidance, free training, and scheduled maintenance support.

-

Customization options: From explosion-proof designs and cleanroom adaptations to vacuum integration, DHT® offers tailor-made solutions to meet specific customer requirements.