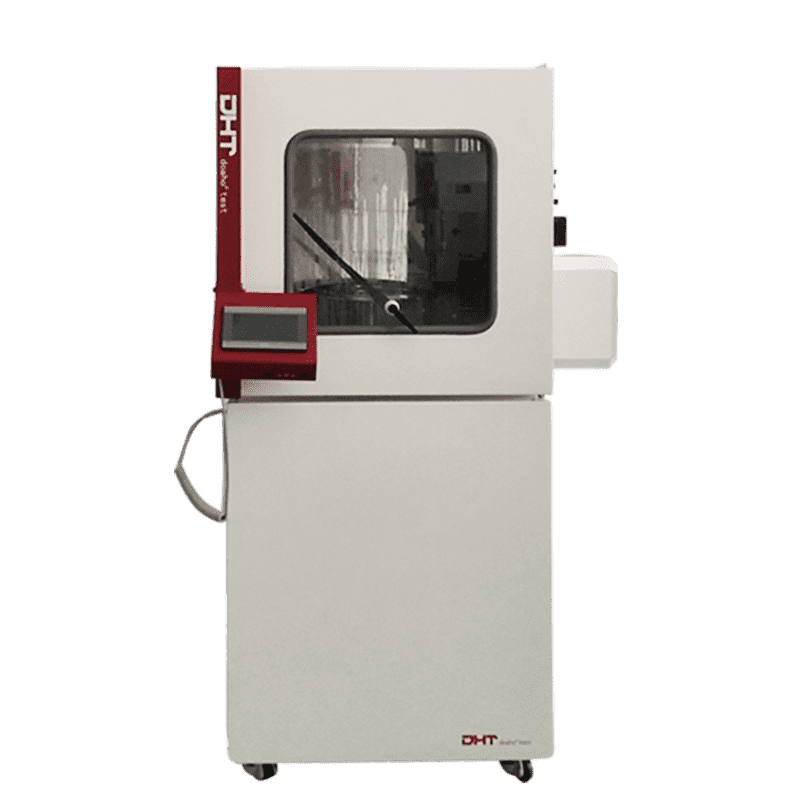

Rain Chambers: Precision Labs That Simulate Natural Rain

-

Multi-Dimensional Spray Matrix Programmable rotating nozzles deliver full-spectrum waterproof testing from IPX1 to IPX9K, including vertical drips, fan sprays, and high-pressure hot water jet impact.

-

Dynamic Environmental Simulation Temperature and humidity ranges from -40°C to +80°C allow compound testing for rainfall plus freezing or high-humidity conditions.

-

Optional Motion Load System Enables dynamic angle adjustment or rotation of test samples to simulate water ingress during real-world motion, such as vehicles in operation.

The Science Behind Rain Testing: More Than Just “Water Splashing”

-

Capillary Penetration ModelingBy calculating capillary effects at structural gaps, the system adjusts spray pressure from 0 to 1000 kPa. For instance:

-

Automotive headlamp seals may require low-pressure (30 kPa) sustained drizzle.

-

EV charging ports may undergo high-pressure (100 kPa) pulsed impact testing.

-

-

Accelerated Aging ModelsIncreasing water temperature to 80°C can dramatically accelerate rubber gasket degradation, simulating six months of hydrolysis within one hour. This is a technical core of advanced rain test chamber services.

Real-World Applications of Rain Test Chambers

● Neue Energiefahrzeuge

● Consumer Electronics

● Defense and Military Systems

● Photovoltaic Energy Equipment

How to Choose a Professional Rain Test Chamber Solution

-

Application Coverage

-

Does the chamber comply with ISO 20653, IEC 60529, or other latest waterproofing standards?

-

Can it accommodate angled spray paths (e.g., 45° diagonal spray for EV charging interfaces)?

-

-

Test Traceability and Data Intelligence

-

Top-tier rain test chambers are equipped with flow sensors and AI-based vision systems that auto-detect leak points and generate 3D water ingress path maps. One inspection lab used this function to pinpoint a 0.2 mm gap in a drone motor housing.

-

-

Ecosystem-Level Rain Test Chamber Services

The real competitive edge lies in expert-level support:-

Customized test plan development (e.g., GJB rain profiles for military-grade devices)

-

Failure mode analysis based on water trajectory backtracking

-

Intelligent maintenance systems (e.g., nozzle wear prediction alerts)

-

-

Future Outlook: Evolving from “Waterproofing” to “Water Management”

As products face harsher water-related environments, leading manufacturers are transforming their approach:-

Smart Drainage System Testing EV battery packs undergo simulated immersion followed by testing of active drainage strategies.

-

Interface Material Science Studies of nano-coatings under dynamic water flows are unlocking new understanding of delamination mechanics.

-

Integration des digitalen Zwillings Test chamber data is now being mapped into CAE models to optimize sealing architecture during design iterations.

-

Final Thoughts: Building Product Resilience Before the Storm Hits

Häufig gestellte Fragen

Was ist eine Regentestkammer und warum ist sie wichtig?

Ein Regenprüfkammer ist ein Umweltsimulationsgerät, das Regen, Straßenspritzwasser und Hochdruckreinigungen simuliert, um die Wasserfestigkeit von Produkten, die Dichtungszuverlässigkeit und die langfristige Haltbarkeit unter realen Bedingungen zu bewerten. Es hilft, Ausfälle wie Leckagen, Kurzschlüsse oder Materialverschlechterung zu verhindern.

Welche Branchen verwenden üblicherweise Regenprüfkammern?

Regenkammern werden häufig in der Automobilindustrie (EV-Batteriepacks, Scheinwerfer, Ladeanschlüsse), Verbraucherelektronik (Smartphones, Wearables), Verteidigungssystemen (Radar, Bordausrüstung) und erneuerbaren Energien (PV-Wechselrichter) eingesetzt. Sie gewährleisten, dass Produkte den IP-, IEC-, ISO- oder militärischen Wasserdichtigkeitsstandards entsprechen.

Was sollten Sie bei der Auswahl einer Regenprüfkammer beachten?

Die Schlüsselfaktoren umfassen die Einhaltung von Standards (ISO 20653, IEC 60529, GJB150.8A), die Flexibilität des Sprühsystems (IPX1–IPX9K, geneigte Düsen), datenintelligente Funktionen (Durchflusssensoren, KI-gestützte Leckerkennung) und Anbietersupport wie kundenspezifische Testpläne, Fehleranalyse und prädiktive Wartung.