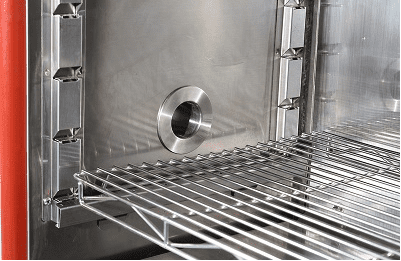

Was ist eine Schnellwechselrate-Prüfkammer?

-1-300x300.png.webp)

-

Ein-Zonen-Kammern, die schnelles Heizen und Kühlen in einer Kammer ausführen, sind ideal für standardisierte Tests.

-

Drei-Zonen-Kammern verwenden mechanische Transportsysteme, um Testproben zwischen heißen, Umgebung- und kalten Zonen zu transportieren, was sie ideal für thermische Schockanwendungen macht.

Warum ist das Testen mit schnellen Temperaturwechseln so wichtig?

-

Frühzeitige Identifizierung potenzieller Produktfehler Diese Art des Testens ermöglicht es Herstellern, Designfehler, Materialinkonsistenzen und Montagefehler früh im Entwicklungszyklus zu erkennen. Häufige Ausfallmodi umfassen Ermüdung der Lötstellen, PCB-Leiterbahnbrüche, Mikrorisse in Kunststoffgehäusen, Klebstoffversagen und Dichtungsabbau. Es deckt auch Probleme auf, wie z.B. Delaminierung aufgrund nicht übereinstimmender thermischer Ausdehnungskoeffizienten zwischen Materialien – was hilft, kostspielige Qualitätsprobleme in der Massenproduktion zu verhindern.

-

Erfüllung von Industriestandards Das Temperaturschnellwechseltesten unterstützt die Einhaltung einer Reihe globaler Industriestandards, darunter:

-

-

MIL-STD-883 (Militärelektronik)

-

IEC 60068-2-14 (allgemeine Elektronik)

-

JEDEC JESD22-A104 (Halbleiter)

-

ISO 16750-4 (Automotivelektronik)

-

Das Bestehen dieser Tests stellt nicht nur Produktzuverlässigkeit sicher, sondern spielt auch eine Schlüsselrolle bei der Erlangung internationaler Zertifikate und Marktzugänge. -

-

Lebensdauerverlängerung von Produkten & Reduzierung von Garantieansprüchen Durch die Simulation jahrelanger Umwelteinwirkungen innerhalb weniger Tage oder Wochen hilft das schnelle Temperaturzyklisieren, langfristige Leistung vorherzusagen, Ausfallraten zu reduzieren und den Markenruf zu verbessern – während gleichzeitig Servicekosten gesenkt und Kundenzufriedenheit gesteigert werden.

-

Sicherstellung der Zuverlässigkeit von Mikroteilen Da Produkte zunehmend kompakt und modular werden, sind ihre internen Strukturen empfindlicher gegenüber thermischer Ausdehnung und Kontraktion. Das macht das Testen mit schnellen Temperaturwechseln besonders wichtig für Mikrokomponenten wie Chips, MEMS-Sensoren und Lithiumbatterien, bei denen thermische Belastung die Leistung und Sicherheit erheblich beeinträchtigen kann.

Wie wählt man die richtige Kammer für Ihre Geschäftsphase

-

Startups: Konzentrieren Sie sich auf Skalierbarkeit. Entscheiden Sie sich für modulare Systeme, die die Grundbedürfnisse erfüllen (z.B. -40℃ bis +130℃), aber bei wachsendem Bedarf auf fortgeschrittene Bereiche (z.B. -70℃ bis +180℃) aufgerüstet werden können.

-

Etablierte Hersteller: Bauen Sie ein integriertes Testökosystem auf. Verbinden Sie Kammern mit MES-Systemen für optimierte Arbeitsabläufe – von Barcode-Scanning und automatisierter Testprogrammierung bis hin zu Echtzeit-Datenerfassung und Berichterstellung.

-

High-End- F&E Labors: Priorisieren Sie extreme Leistungen. Halbleiterunternehmen benötigen möglicherweise Rampenraten von 30℃/min mit Flüssigstickstoffkühlung, um den Wärmeaufbau in 3D-verpackten Chips zu simulieren.

-

Achten Sie auf "Spezifikationsblattfallen": Ein Labor geriet in diese häufige Falle – verließ sich auf eine angegebene Rampenrate von 15℃/min, ohne zu beachten, dass dies für eine leere Kammer galt. Beim Testen eines vollständig beladenen Automotive-ECU sank die reale Rampenrate auf 5℃/min, was zu ungültigen Testergebnissen und verlorener Zeit führte.

Die Zukunft des Schnellwechseltestens

"Nach 1.500 Zyklen von -40℃ bis +105℃ entdeckten wir thermische Geräuschprobleme in unseren CMOS-Bildsensoren bei rund 85℃. Diese Erkenntnis führte dazu, dass wir den Wärmeableitungspfad neu gestalteten und das Signal-Rausch-Verhältnis unseres Nachtsichtsystems um 471% verbesserten." — Chefingenieur, Automotiv-Kamerahersteller

Fazit: Die Grundlagen der Zuverlässigkeit schaffen

"Wir testen nicht die Temperaturen – wir testen die Würde unserer Produkte unter Druck."

Häufig gestellte Fragen

Was ist eine Schnellwechselrate-Kammer?

Eine Schnellwechselkammer ist ein spezialisiertes Umwelttestgerät, das entwickelt wurde, um Produkte oder Materialien unter kontrollierten Bedingungen schnellen und häufigen Temperaturschwankungen auszusetzen, mit Wechselraten von 3°C bis 30°C pro Minute. Es hilft, extreme thermische Bedingungen der realen Welt wie Hochflüge, Kaltstarts und Transport in rauen Klimazonen zu simulieren.

Warum sind Schnelltemperaturwechseltests entscheidend für die Zuverlässigkeit von Produkten?

Schneller Temperaturwechsel hilft dabei, Designfehler, Materialunregelmäßigkeiten und Montagefehler frühzeitig zu erkennen, was die Zuverlässigkeit von Mikrotechnologiekomponenten gewährleistet, die Produktlebensdauer verlängert, Garantieansprüche verringert und die Einhaltung internationaler Standards wie MIL-STD-883, IEC 60068-2-14 und JEDEC JESD22-A104 unterstützt.

Wie sollten Unternehmen die richtige Schnell-Wechselrate-Kammer auswählen?

Die Auswahl hängt von der Geschäftsphase und den Produktanforderungen ab: Start-ups können modulare Systeme mit skalierbaren Bereichen wählen, etablierte Hersteller profitieren von integrierten Testökosystemen mit Echtzeitüberwachung, und High-End-F&E-Labore können extrem hohe Rampenraten für Mikroelektronik- und Halbleiteranwendungen benötigen.