Why Full-Vehicle Validation Requires a Walk-In Environmental Chamber?

-

Accommodates entire vehicles (passenger or commercial) or large integrated systems

-

Simulates a wide range of extreme environments: temperature (-40°C to +80°C), humidity (10%–98% RH), wind speed, rain, and low atmospheric pressure

-

Supports testing for battery thermal runaway, high-voltage system stability, high-heat exposure, cold-start conditions, and more

-

Suitable for various stages including prototyping, regulatory certification, and long-term durability validation

Practical Applications: Real-World Value of Walk-In Chambers

-

Full-Vehicle Thermal Performance Testing

-

Cold-start testing at temperatures as low as -30°C

-

High-load system operation under heat conditions up to +70°C

-

Rapid thermal cycling to assess component stress and system resilience

-

Battery and High-Voltage System Testing

-

Full-vehicle thermal aging and thermal management assessments

-

Simulation of thermal runaway events and mitigation strategies

-

BMS, inverters, and drive systems tested under dynamic temperature and humidity

-

Water & Dust Resistance Validation

-

Evaluating water ingress in door seals, sunroofs, and cable entry points

-

Simulating high-wind, dust-laden environments

-

Conducting IPX4, IP5X, and IP6K ingress protection certification tests

-

Material Aging & VOC Emission Testing

-

UV exposure, alternating heat-humidity stress cycles

-

Dynamic VOC emission changes (TVOC, formaldehyde, etc.)

-

Long-term aging of trim, adhesives, and sealing materials

Cost-Effectiveness: Long-Term ROI of Walk-In Chambers

-

Streamlined Testing, Shorter R&D Cycles

-

Lower Total Cost of Ownership

-

Avoiding redundant purchases and energy costs from multiple systems

-

Minimizing manpower and time lost to repeated test configurations

-

Reducing outsourced testing fees—especially critical for confidential projects

-

High-Value Data Integration

-

High-resolution environmental and operational test data

-

Accurate root cause analysis and design optimization

-

Data-backed insights for after-sales improvements and product reliability

-

Compliance-Ready Testing Infrastructure

-

Test scope and protocol compliance

-

Certification speed and approval success rates

-

Global market accessibility

Who Should Consider a Walk-In Environmental Chamber?

-

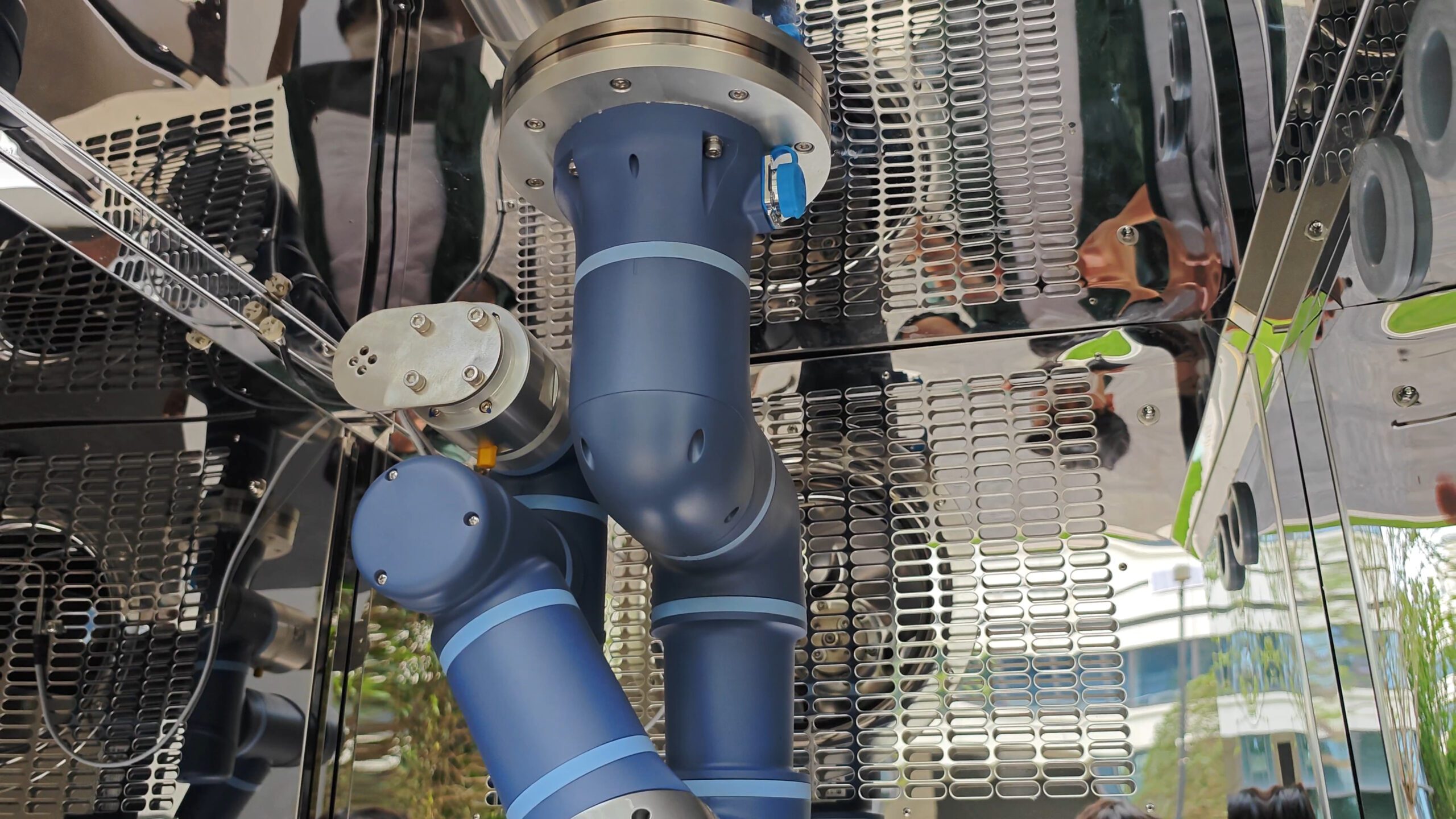

Vehicle OEMs & Tier-1 Suppliers: For full-vehicle or integrated system testing

-

EV System Manufacturers: For battery packs, HVAC, and high-voltage architecture validation

-

Autonomous Driving & Smart Cockpit Developers: To test sensors, cameras, and control units in extreme environments

-

Third-Party Testing Labs: Offering environmental testing services to OEMs and component manufacturers

-

Special Vehicle & Custom Coach Builders: For high-altitude, polar, or military-grade environmental performance validation

Conclusion: Creating Controlled Extremes for Global Automotive Readiness

Häufig gestellte Fragen

Warum benötigen Automobilhersteller begehbare Umweltsimulationskammern?

Da Fahrzeuge hochintegrierte Systeme sind, können Tests auf Komponenten- oder Subsystemebene die Leistung in der realen Welt nicht vollständig widerspiegeln. Eine begehbare Kammer ermöglicht die Validierung des gesamten Fahrzeugs unter extremen Bedingungen wie Temperaturen von -40°C bis +80°C, Luftfeuchtigkeit bis zu 98% RH, Wind, Regen und niedrigem Druck, um Sicherheit, Zuverlässigkeit und Konformität sicherzustellen.

Welche Arten von Tests können in einer begehbaren Umweltkammer durchgeführt werden?

Begehbare Kammern unterstützen das thermische Leistungstest von vollständigen Fahrzeugen, die Validierung von Batterie- und Hochspannungssystemen, die Zertifizierung von Wasser- und Staubeintritt, Materialalterungsstudien und die Analyse von VOC-Emissionen. Sie simulieren mehrere extreme Bedingungen—Kaltstarts, thermisches Durchgehen, UV-Belastung und kombinierte Feuchtigkeits-Temperatur-Zyklen.

Welche Kosten- und Effizienzvorteile bieten Walk-In-Kammern?

Obwohl Begehungskammern eine höhere Anfangsinvestition erfordern, senken sie die langfristigen Kosten, indem sie mehrere Tests in einem Aufbau konsolidieren, F&E-Zyklen verkürzen, externe Testgebühren senken und die Zertifizierungsbereitschaft verbessern. Die integrierte Datenerfassung unterstützt auch die Ursachenanalyse, Designoptimierung und globale Marktkonformität.