Written by Dorothy

Senior Sales Manager, Doaho Test (DHT®)

Innovation Backed by Rigorous Testing

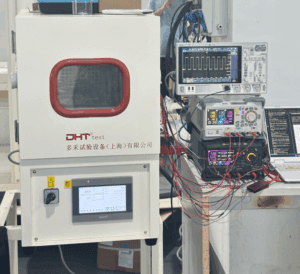

Recently, a student research team from Peking University, under the guidance of their professors, successfully developed a new type of temperature sensor designed to improve stability and sensitivity under extreme environmental conditions. To verify the reliability of their innovation, the team partnered with DHT®, utilizing our advanced constant temperature and humidity chambers for comprehensive performance testing.

This collaboration represents not only a perfect integration of academic research and industrial application but also a strong testament to DHT®’s commitment to supporting technological innovation and fostering engineering talent.

Peking University’s Technological Breakthrough

The temperature sensor developed by the Peking University team marks a significant step forward in the field of Industrial IoT. Characterized by high precision, low power consumption, and miniaturization, the sensor is expected to find applications across intelligent manufacturing, medical devices, environmental monitoring, and other critical sectors.

“We needed to verify the sensor’s stability and accuracy under drastic temperature fluctuations, as this directly impacts its reliability in real-world applications,” said the team leader.

While the students had already completed fundamental functional testing, proving the sensor’s adaptability in real-world scenarios required specialized environmental reliability testing. This was the primary reason they sought the support of DHT®’s professional testing equipment.

The Critical Role of DHT® Chambers

DHT® provided the team with its latest series of constant temperature and humidity chambers, capable of precisely simulating a wide range of conditions—from extreme low temperatures to high heat—while maintaining stable humidity levels.

The testing program included three key stages:

-

Cold-start testing within a range of -40℃ to +25℃, evaluating response performance in extremely low temperatures.

-

Thermal stability testing between +25℃ and +85℃, assessing accuracy under high-temperature conditions.

-

High-humidity endurance testing, ensuring long-term operational stability.

“We paid special attention to how rapid temperature changes affect sensor accuracy,” explained one of the testing engineers. “The chamber’s ability to achieve temperature shifts at a rate of 5℃ per minute provided us with invaluable data.”

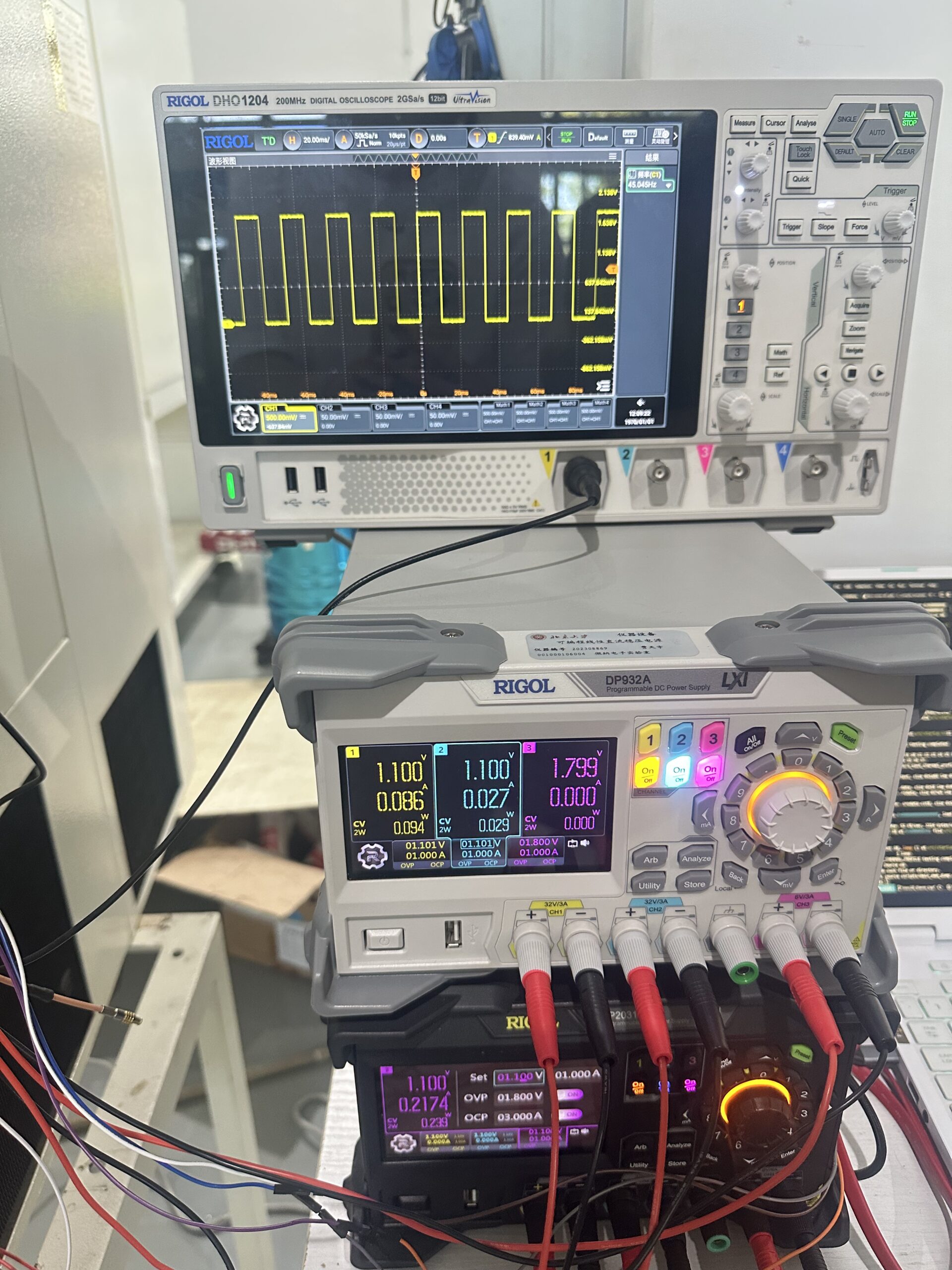

Testing Parameters and Performance Validation

Throughout the process, DHT® chambers demonstrated exceptional performance. Temperature was controlled with an accuracy of ±0.5℃, and humidity deviation was maintained within ±2% RH, ensuring both reliability and repeatability of results.

The team established several critical performance metrics: sensor response time across varying temperature points, measurement accuracy, power consumption variations, and long-term stability. Each metric was tested under rigorously controlled conditions and repeated multiple times to ensure statistical significance.

“What impressed us most was the chamber’s environmental uniformity,” a student team member commented. “Temperature variations across different points within the chamber were less than ±1℃, providing us with highly consistent testing conditions.”

Academic-Industrial Collaboration Driving Innovation

This project also highlights DHT®’s commitment to supporting academic research. Beyond providing access to advanced testing equipment, DHT® assigned a dedicated technical team to work alongside the students, helping optimize testing protocols and interpret results.

“Collaborating with the Peking University team gave us invaluable feedback,” said the DHT® Technical Director. “Their innovative thinking and rigorous approach were truly impressive, and some of the testing scenarios they proposed even inspired us to improve our own product design.”

This kind of collaboration between academia and industry is becoming a vital driver of technological advancement—where universities contribute pioneering ideas and technologies, while industry provides real-world platforms and experience to accelerate practical application.

DHT®’s Expertise and Vision

Since its founding, DHT® has remained dedicated to the research, development, and manufacturing of environmental testing equipment. Our products are widely applied in industries such as new energy vehicles, batteries, electronic components, aerospace, semiconductors, and research institutions.

We maintain leadership in the following areas:

-

Independent R&D – Holder of multiple patents, continuously advancing temperature and humidity control technologies.

-

Customized Solutions – Offering non-standard equipment tailored to unique testing scenarios.

-

Compliance with International Standards – Fully aligned with GB/T, IEC, MIL-STD, UN38.3, and other industry standards.

-

Global Service Network – Supporting customers not only in China but also across Europe, North America, and Southeast Asia.

Looking ahead, DHT® will continue to uphold its mission: “Making testing more precise, making the world safer.” We are committed to helping research institutions and enterprises worldwide improve product reliability and competitiveness.

Conclusion

The successful validation of Peking University’s new temperature sensor using DHT® chambers demonstrates outstanding sensor performance under complex environmental conditions. This achievement exemplifies the synergy between academic innovation and engineering practice, as well as the importance of collaboration between education, research, and industry.

As a professional manufacturer of environmental testing equipment, DHT® remains committed to providing advanced and reliable testing solutions to global partners. We firmly believe that only through rigorous environmental validation can scientific breakthroughs truly be transformed into practical applications that benefit society.

DHT® — Your Trusted Partner in Environmental Testing.

FAQ

What is the role of DHT® Constant Temperature and Humidity Chambers in product testing?

DHT® chambers are designed to simulate extreme temperature and humidity conditions, ensuring that products such as sensors, batteries, and semiconductors can withstand real-world environmental stresses. They provide precise control of temperature (±0.5℃) and humidity (±2% RH), allowing researchers and engineers to evaluate performance, reliability, and durability under harsh conditions.

Why did the Peking University research team choose DHT® chambers for their sensor testing?

The Peking University team required highly accurate and stable testing equipment to validate their new temperature sensor under drastic environmental fluctuations. DHT® chambers offered rapid temperature cycling (up to 5℃ per minute), exceptional environmental uniformity (±1℃ across different points), and reliable long-term performance, making them an ideal choice for advanced academic research.

What advantages do DHT® Constant Temperature and Humidity Chambers provide compared to other solutions?

DHT® chambers combine wide temperature ranges (-70℃ to +180℃), stable humidity control, and strong durability with customizable solutions tailored to different industries. They comply with international standards (GB/T, IEC, MIL-STD, UN38.3) and are supported by a global service network. These advantages make them suitable not only for universities but also for industries like aerospace, automotive, electronics, and semiconductors.