Written by Robin

Senior Engineer, Doaho Test (DHT®)

In today’s fast-paced global manufacturing competition, even the slightest crack in a solder joint or the smallest sign of material fatigue can trigger product failures—and even threaten the reputation of an entire brand. When your products must withstand the harshest environmental challenges, traditional slow temperature cycling tests are no longer sufficient. What you need is a testing solution that can replicate instant and extreme temperature transitions, precisely revealing potential weaknesses.

The DHT® Thermal Shock Chamber was designed for exactly this purpose. More than just a piece of equipment, it is your strategic partner in reliability assurance—safeguarding the lifeline of product quality through high-efficiency testing, and empowering advanced manufacturing with uncompromising confidence.

Why Thermal Shock Testing Is Essential

Unlike conventional temperature and humidity tests, Thermal Shock Testing simulates the harsh conditions of products undergoing rapid transitions between extreme high and low temperatures.

The primary objective is to accelerate the exposure of potential weaknesses in materials, assembly processes, and structural design under sudden thermal stress.

For example, due to mismatched coefficients of thermal expansion (CTE) among different materials, rapid hot-cold transitions generate significant internal stress, which can lead to:

-

Semiconductor package cracking

-

PCB plated through-hole (PTH) failures

-

Component solder joint fatigue or detachment

-

Coating delamination and seal failure

Such failures are often invisible under slow temperature changes, yet they can suddenly occur during shipping, storage, or real-world operation—causing costly after-sales issues and severe brand damage.

A Thermal Shock Chamber capable of precise, rapid, and reliable temperature transitions is therefore an indispensable tool for identifying and eliminating these risks in advance.

DHT® Mini Thermal Shock Test Chamber

Extreme Performance, Precision Control

Equipped with a proprietary intelligent control system and an advanced air circulation design, DHT® chambers cover a wide temperature range from -70°C to +220°C, with uniformity as tight as ±0.5°C, ensuring absolute accuracy and repeatability.

Military-Grade Quality, Globally Sourced Components

Every core component is globally selected: European controllers, German Bitzer compressors, French Schneider electrical parts, American Honeywell sensors, and Japanese Omron relays and switches. The chamber interior is welded from stainless steel in a single-piece structure, providing excellent corrosion resistance and durability against thermal stress.

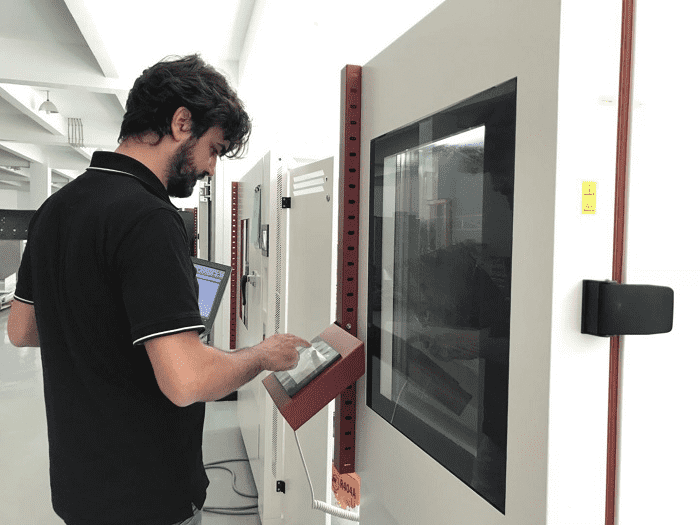

Smart Control, Efficient Management

Powered by a PLC control system, DHT® chambers allow pre-programming of test cycles with fully automated operation. A touch-screen interface supports programmable runs, data logging, and remote monitoring, while compatibility with mainstream laboratory management systems ensures streamlined test administration.

Ultra-Low Failure Rate & Extended Service Life

With internationally recognized first-tier components, DHT® chambers deliver ultra-low failure rates and a service life exceeding 25 years, significantly reducing long-term maintenance costs.

Energy-Efficient, Environmentally Friendly

Intelligent refrigeration and zone control reduce energy consumption by up to 30%, achieving sustainable operation without compromising performance.

Multi-Layer Safety Protection

Built-in safeguards include overpressure protection, leakage protection, and over-temperature protection, ensuring testing is safe and reliable throughout the process.

Custom Solutions for Diverse Applications

DHT® provides powerful customization capabilities, supporting non-standard dimensions, three-zone systems, and liquid nitrogen deep-cooling options. Available in volumes ranging from 100L to 1500L, DHT® solutions cover a broad spectrum of testing needs—from electronic components and small modules to full system assemblies.

Customers also benefit from a 5-year extended warranty, 24/7 technical support, remote monitoring, and diagnostic services, forming a comprehensive and intelligent service ecosystem.

High Performance at Competitive Cost

In global competition, DHT® stands out with a compelling price-performance advantage: equipment costs are only 60%–70% of international brands, while delivering performance that matches—or even surpasses—imported systems. This value proposition has made DHT® the first choice for many enterprises.

| DHT® Mini Thermal Shock Test Chamber(Two-Zone) | ||

| TemperatureChamberModel | Model | DHTT-27-M |

| Working Room Volume | L | 27 |

| Temperature Range | ℃ | (Pre-heating)+180 (Pre-cooling)-65 |

| ThermaShock Range | ℃ | (-40,-50,-60)~+(+80,+120,+150) |

| Heating Rate | °C/min | 2.0~4.0 |

| CoolingRate | °C/min | 0.7~3.5 |

| Temperature Fluctuation | ℃ | ±0.1~±0.5 |

| Temperature Uniformity | ℃ | 0.5~2.0 |

| Testing Mode | Lift-and-shift switching | |

| Transfer Time | S | <15 |

| Transfer Mode | Pneumatic | |

| Tempearture Recovering Time | min | 5 |

| Internal Dimensions | W(mm) | 300 |

| D(mm) | 300 | |

| H(mm) | 300 | |

| External Dimensions | W(mm) | 500 |

| D(mm) | 1100 | |

| H(mm) | 1330 | |

| Cooling Mode | Air Cooling | |

| Power Voltage | 220V±10%,50~60Hz | |

| Rated Power | 5kW | |

Conclusion

With exceptional transition speed, precise and stable temperature control, robust system architecture, and flexible customization, DHT® Thermal Shock Chambers are trusted by a growing number of advanced manufacturers as guardians of product reliability.

They are not merely testing devices, but strategic partners supporting the entire product lifecycle—from R&D and validation to final delivery.

Choosing DHT® means choosing a future-oriented approach to reliability management. It enables enterprises to meet stringent international standards, stay ahead in fierce global competition, and safeguard the lifeline of quality through high-efficiency testing.