Written by Robin

Senior Engineer, Doaho Test (DHT®)

While you’re scrolling through short videos on your phone, the device may be quietly enduring subtle “thermal shocks.” From scorching car interiors to air-conditioned offices, from freezing northern regions to hot coastal environments—electronic devices must withstand drastic temperature swings. What you may not realize is that behind every device that survives such conditions is an extreme test known as the thermal shock chamber. This article skips theory and instead goes straight into how this unassuming yet critical equipment plays a vital role in product reliability.

Who Needs Thermal Shock Testing? Every Segment of Electronics Relies on It

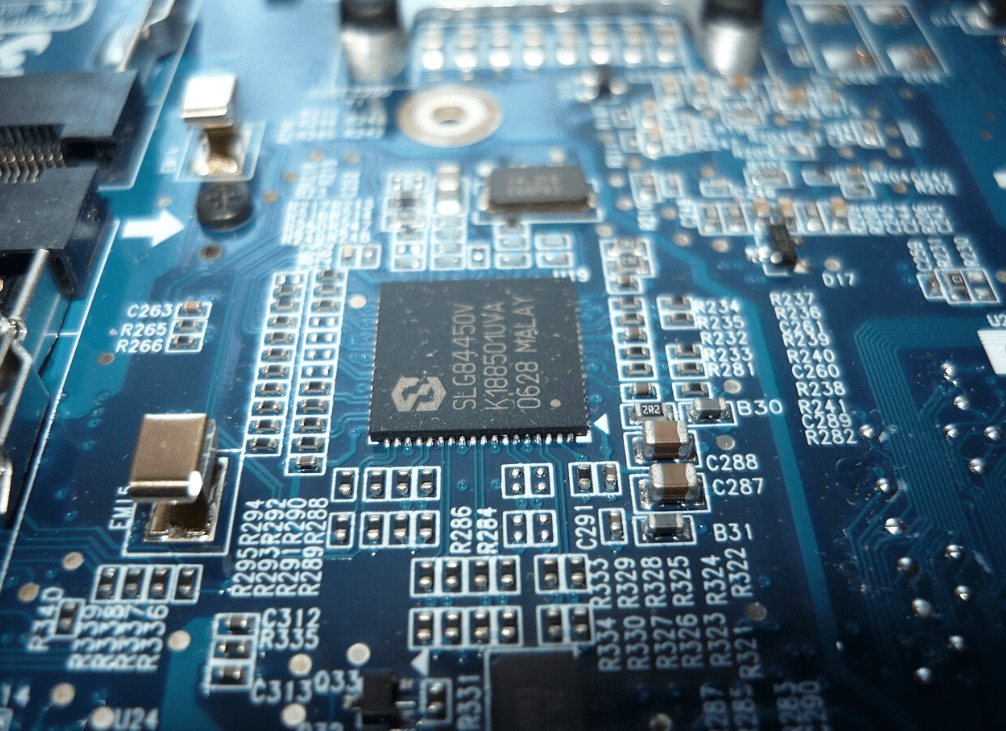

Temperature-induced damage is often underestimated. Components that seem innocuous—PCB solder joints, chip packaging, connector wiring, and housing seals—can all become breakpoints under rapid temperature changes.

A thermal shock chamber allows products to endure real-world extremes in a controlled lab setting, enabling early detection and reinforcement of vulnerable points. Across consumer electronics, automotive electronics, 5G devices, military hardware, and medical instruments, thermal shock chambers have become indispensable tools in product validation. In just a few seconds, these chambers can transition from high to low temperature (or vice versa), simulating a “thermal hell” environment and delivering accelerated aging assessments.

What Happens Inside a Thermal Shock Chamber? Behind-the-Scenes Simulation

If you think thermal shock testing is just “heat up → cool down → repeat,” think again. A professional thermal shock chamber typically offers:

-

Three-chamber design (hot zone – cold zone – test zone): Samples transfer between temperature zones to replicate instantaneous thermal shock.

-

Wide temperature range: Capable of handling environments from –70 °C up to +180 °C to simulate everything from extreme cold to scorching heat.

-

Rapid transfer time: Temperature changes achieved in around 5 seconds to ensure authentic thermal stress.

-

Precise dwell control: Helps identify materials or designs with delayed thermal response issues.

-

Comprehensive data logging: Tracks temperature profiles, sample conditions, and alarms to support analysis and traceability.

Real-world example: An industrial sensor manufacturer tested a new PCB packaging method. During thermal shock testing, micro-cracks repeatedly appeared around solder joints. Engineers found a thermal expansion mismatch between the packaging material and solder. If this issue had escaped detection until after product launch, the consequences would have been costly.

Driving Innovation in Electronics: Beyond Temperature Cycling

Today’s electronics aren’t just used in climate-controlled offices—they’re deployed in deserts, high altitudes, coastal zones, even orbiting satellites. This reality raises two major demands on product development:

-

High design tolerance: Thermal shock testing reveals “fatal flaws” early in the development cycle.

-

Robust materials and packaging: Temperature-induced expansion differences between materials can lead to fatigue or solder joint failure.

Leading-edge companies now treat thermal shock chambers not just as reliability filters but as design validation tools:

-

Packaging reliability testing: Use on BGA chips, LED modules, CMOS sensors to assess solder joint longevity through cyclic thermal stress.

-

New material adaptation testing: Evaluate behaviors of materials like nano-ceramics, flexible substrates, and graphene heat-spreading films under rapid temperature changes.

-

System-level validation: For example, testing 5G micro base stations to ensure performance remains stable post thermal shock.

-

Fatigue failure modeling inputs: Providing data for CAE simulations to optimize structural design.

How to Choose the Right Thermal Shock Chamber for Your Needs

Selecting a thermal shock chamber is not like buying office equipment—it requires deep consideration. Professional buyers typically evaluate:

-

Zone temperature stability and transition speed: Faster transitions and wider temperature swings provide a more realistic stress test.

-

Sample capacity and configuration compatibility: Chamber size is critical whether you’re testing small components or full systems.

-

Smart control features: Remote operation, real-time data uploads, and automatic fault alerts increase efficiency.

-

Ease of maintenance and diagnostic capability: Self-diagnostic features and readily replaceable wear parts are essential.

-

Standards compliance: Especially important for military (MIL-STD), electronics (JEDEC), or export-oriented testing applications.

Ideally, procurement decisions should involve testing engineers, product owners, and quality teams to align device selection with product roadmap over the next 3–5 years.

In Summary: True Reliability Is Built on Verification, Not Just Design

Every successful electronic product stands on the foundation of invisible testing systems. Among them, thermal shock testing presents the harshest environmental challenge. A thermal shock chamber isn’t simply a piece of equipment; it’s a litmus test of an electronics design’s fault tolerance.

In an era that demands faster, slimmer, and more stable products, using a high-performance thermal shock chamber during the design stage may be the most valuable investment your team can make. If you want to avoid your product being “defeated by its environment” post-launch, this is where reliability begins.

DHT® is committed to delivering stable, precise, and high-reliability environmental testing solutions that help electronics companies gain a competitive edge. If you’re interested in partnering with a trusted supplier of thermal shock chambers, please contact our engineering team to receive tailored testing advice and selection support.

People also ask

What is the primary function of a thermal shock chamber, and why is it essential in the electronics industry?

The core function of a thermal shock chamber is to simulate extreme temperature fluctuations to evaluate how well a product can endure sudden thermal stress. In the electronics industry, failures like solder cracking, material fatigue, or seal breakdown are often caused by rapid temperature changes. That’s why thermal shock testing has become indispensable across consumer electronics, automotive systems, military-grade hardware, and more.

How does a thermal shock chamber work, and how is it different from conventional temperature test equipment?

A thermal shock chamber typically uses a multi-zone (often three-chamber) system—hot, cold, and test zones—where samples are rapidly transferred between zones to simulate instantaneous temperature shifts. This physical movement, combined with wide-ranging temperature extremes, creates a much more realistic and intense stress environment compared to standard temperature chambers. The goal is to test how materials and components respond under sudden, extreme changes, not just prolonged heat or cold.

What key features should we consider when selecting a thermal shock chamber for our business?

When choosing a thermal shock chamber, focus on the following:

-

Temperature range and transition speed: Greater ranges and faster transitions deliver more realistic stress simulations.

-

Sample compatibility: The chamber volume must accommodate your product’s size and test batch size.

-

Smart controls: Look for remote operation, real-time data logging, and auto-alerts.

-

Compliance with industry standards: Especially if your products are for military, automotive, or export markets.

-

Ease of maintenance: Built-in diagnostics and easy part replacements are crucial. It’s best to involve cross-functional teams—engineering, R&D, and QA—in the evaluation to ensure a strategic long-term investment.