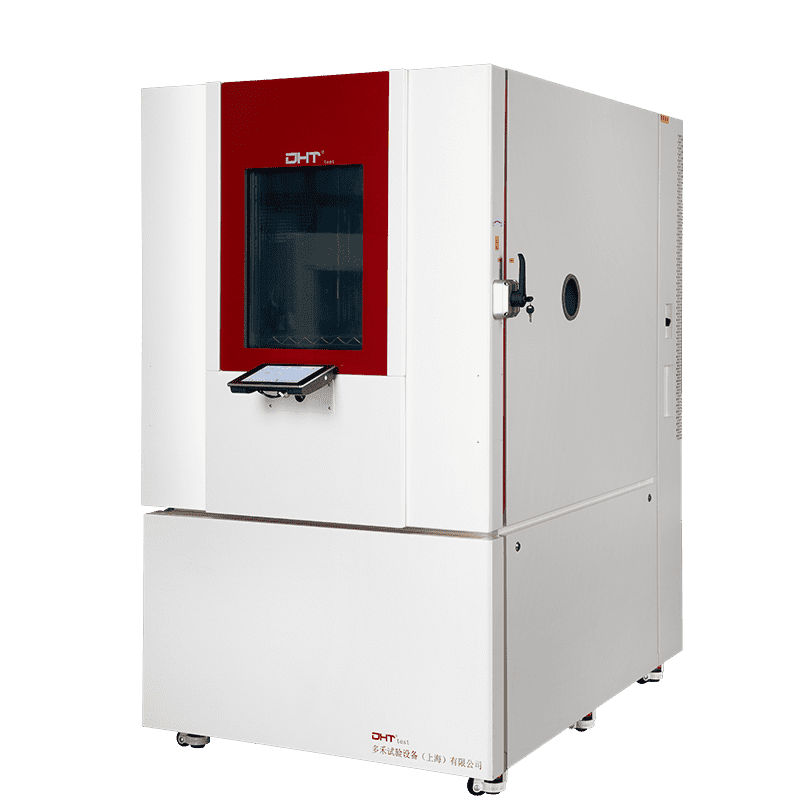

La chambre d'essai de condensation DHT® est conçue en stricte conformité avec les normes internationales ISO 6270-2 et DIN EN ISO 6270-2, permettant des tests de corrosion accélérés qui reproduisent fidèlement les mécanismes de changement de phase de la condensation grâce à un contrôle précis des conditions de vapeur d'eau saturée.

Cette chambre est spécifiquement conçue pour évaluer quantitativement la résistance à la corrosion des revêtements de protection comme les peintures anticorrosion et les couches électrophorétiques, ainsi que les substrats métalliques (y compris les surfaces plaquées et alliées) sous une exposition continue à la condensation. Elle convient également idéalement aux tests de résistance à l'humidité des connecteurs électriques automobiles, des composants structurels et des matériaux d'emballage électronique.

Scientifiquement conçue pour se conformer pleinement à la clause 4 de l'ISO 6270-2:2017—qui nécessite que la température de l'échantillon reste en dessous du point de rosée—le système réduit considérablement les temps de cycle de corrosion tout en maintenant l'intégrité des tests. Les données résultantes offrent une base solide pour le choix des matériaux, l'optimisation des processus anticorrosion et la standardisation du contrôle qualité. Sa corrélation avec le comportement de corrosion extérieur a été validée par SAE J2334, avec un indice de pertinence vérifié dépassant 0.89.

Pour plus de perspicacité, consultez notre article : Lorsque vous choisissez une chambre d'essai de température et d'humidité, devez-vous privilégier les caractéristiques techniques ou le service après-vente ?