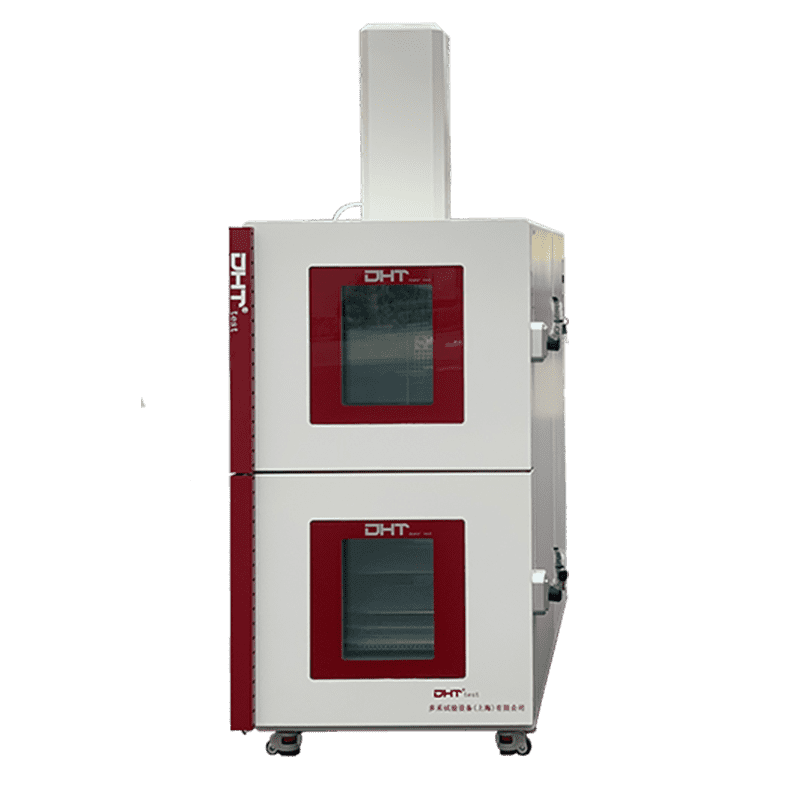

The DHT® Thermal Shock Chamber (Two-Zone) is an advanced thermal cycling test system designed to simulate rapid temperature fluctuations between extreme heat and cold. It is ideal for evaluating material reliability, component fatigue, and failure resistance in high-performance industries.

Available in various configurations—including air-gap two-zone and optional three-zone models—the chamber supports testing volumes from 27L to 1000L, making it highly scalable for R&D and production environments.

Equipped with a PLC-based intelligent control system and user-friendly display, operators can program thermal cycling test parameters for fully automated and repeatable testing. The system delivers rapid temperature transfer between the hot zone (+50°C to +220°C / optional +250°C) and cold zone (-80°C to +70°C), ensuring compliance with standards like IEC 60068-2-14, MIL-STD-883, and more.

Whether you’re testing metals, plastics, PCBs, or aerospace components, this temperature shock chamber provides precise environmental simulation with optimized load capacity—up to 50 kg in three-zone versions. The robust construction, corrosion-resistant materials, and reliable sample transfer system ensure durability and safety, even under harsh test conditions.

Looking for a reliable thermal shock testing solution? The DHT® two-zone chamber delivers performance, flexibility, and compliance in one compact system.

👉 Learn more: Qu'est-ce qu'une chambre d'essai de choc thermique et comment fonctionne-t-elle ?

👉 Troubleshooting Tips: Comment dépanner les chambres d'essais à choc thermique ? Recommandations pour les chambres à chocs thermiques de haute qualité