Qu'est-ce que c'est Chambre d'essai de poussière de sable?

Principes de fonctionnement des Chambres de Test de Poussière de Sable

-

Système de flux d'air Équipée de souffleurs et de conduits intégrés, la chambre crée un flux d'air en boucle fermée qui transporte de manière forcée les particules de poussière dans la chambre de test, simulant le processus dynamique de sablage dans la nature. La vitesse du vent est ajustable en continu, variant généralement de 1,5 m/s à 10 m/s, pour répondre aux diverses exigences de test standard.

-

Système de distribution et de recyclage de la poussière Les matériaux de poussière sèche standardisés (tels que la poudre de talc, la poussière de silicate et le fin de sable) sont continuellement circulés et réintroduits pendant le test. Ce système assure une concentration uniforme de poussière sans accumulation tout au long de la durée du test, maintient la cohérence et la stabilité.

-

Contrôle de la température et de l'environnement Pour simuler de manière réaliste les conditions désertiques à haute température, la chambre est équipée d'un système de chauffage pouvant élever la température de l'environnement au-dessus de 50°C. Certains modèles avancés prennent également en charge le contrôle à faible humidité pour améliorer l'adaptabilité aux environnements combinés chaleur sèche.

-

Système de contrôle et de surveillance Les contrôleurs PLC intégrés et les interfaces homme-machine permettent de définir précisément la durée du test, la vitesse du vent, les intervalles d'injection de poussière et les paramètres de température. Les fonctionnalités d'acquisition de données en temps réel et de surveillance à distance répondent aux besoins de gestion des laboratoires numériques modernes.

Domaines d'application typiques des tests de poussière de sable

-

Équipements militaires et spéciaux Les équipements de combat sur le terrain, les systèmes de communication militaires et les composants de contrôle des missiles doivent résister aux conditions extrêmes de vent et de sable dans les déserts et les hautes terres. Les tests de sable et de poussière évaluent de manière exhaustive la fiabilité et la stabilité des joints, des connecteurs et des câbles dans des environnements abrasifs.

-

Industrie automobile Les composants automobiles tels que les phares, les serrures de porte, les capteurs et les modules de contrôle sont exposés toute l'année à l'extérieur. Utiliser une chambre de test de sable et de poussière soufflée pour la certification IP évalue efficacement la résistance à la poussière et au sable afin de prévenir les dysfonctionnements causés par l'intrusion de particules.

-

Équipements de communications et de puissance Les appareils déployés en extérieur comme les stations de base 5G, les onduleurs solaires et les armoires de distribution électrique sont sujets à la surchauffe et aux courts-circuits si le scellement contre la poussière est inadéquat. Les tests de poussière de sable aident à identifier les défauts potentiels de conception, améliorant la qualité et la fiabilité de l'ingénierie.

-

Maison intelligente et éclairage extérieur Les produits extérieurs tels que les lumières de jardin, les caméras de sécurité et les haut-parleurs extérieurs exigent également des tests de poussière de sable pour vérifier la performance de protection à long terme, prolonger la durée de vie et réduire les coûts de maintenance après-vente.

Aperçu des normes de test courantes

-

IEC 60529: Définit les méthodes de classement de protection contre l'intrusion (IP), avec IP5X et IP6X concernant spécifiquement la protection contre la poussière.

-

MIL-STD-810H (Méthode 510.7): Norme de test environnemental du Département de la Défense des États-Unis détaillant la distribution de la taille des particules, la durée du test, la concentration de poussière et la vitesse de l'air dans les tests de sable et de poussière.

-

GB/T 2423.37: Norme nationale chinoise pour les tests d'adaptabilité environnementale des produits industriels dans des conditions de poussière soufflée.

-

SAE J575: Norme du système d'éclairage automobile spécifiant les exigences de résistance à la poussière.

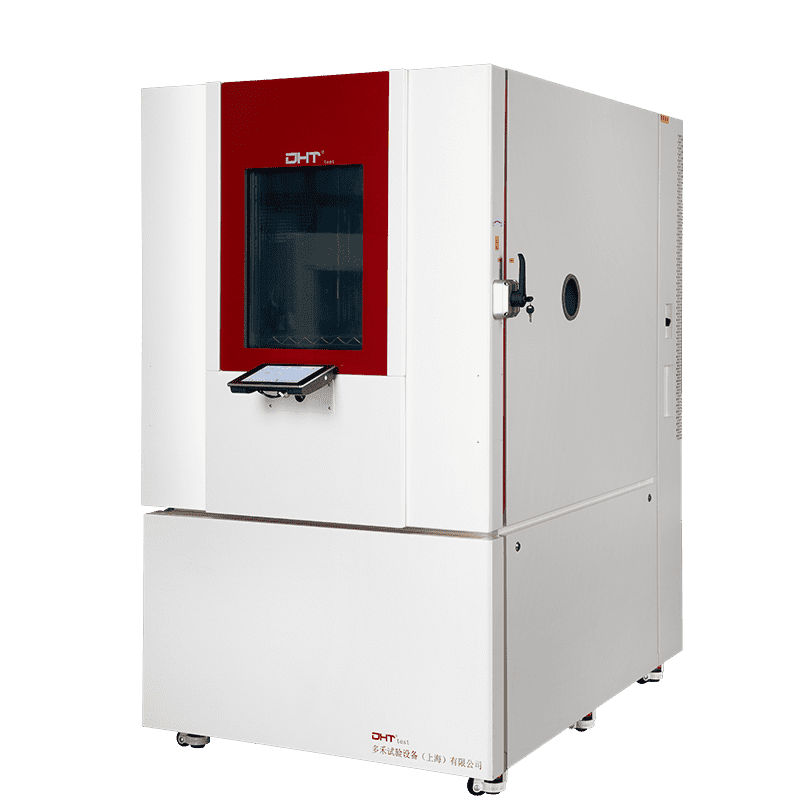

Comment choisir une Chambre de Test de Poussière de Sable hautes performances ?

-

Grande précision dans le contrôle de la vitesse du vent et de la concentration de poussière pour garantir des résultats de test reproductibles et vérifiables ;

-

Conception structurelle modulaire pour un placement d'échantillons facile, nettoyage, entretien et flexibilité de personnalisation ;

-

Conformité à plusieurs normes internationales de test soutenant les tests de résistance IP, poussière et sable ;

-

Grande capacité d'opération stable à long terme pour des tests continus et intensifs ;

-

Systèmes de contrôle intelligents avec opération à distance pour simplifier les flux de travail et augmenter l'efficacité de laboratoire.

Conclusion : Test de Poussière de Sable—Une étape critique pour la vérification de l'adaptabilité environnementale

FAQ

What does a Sand Dust Test Chamber simulate and why is it important?

A Sand Dust Test Chamber replicates natural sandstorm environments by controlling wind speed, dust concentration, and temperature. It helps engineers assess a product’s sealing, protection level, and reliability under harsh outdoor conditions—critical for industries like automotive, military, and electronics.

Which testing standards are used for sand and dust testing?

Liste de contrôle pour éviter les erreurs coûteuses :

IEC 60529 for IP5X/IP6X dust ingress protection

MIL-STD-810H (Method 510.7) for military-grade sand/dust resistance

GB/T 2423.37 for general industrial product testing

SAE J575 for automotive lighting systems

These standards ensure results are scientifically valid and globally recognized.

What features should I look for when selecting a sand dust test chamber?

Look for:

Precise control of wind speed and dust concentration

Modular design for easy maintenance and customization

Compliance with international standards (IP, MIL, IEC, etc.)

Intelligent control systems with remote monitoring

Proven stability for long-term, intensive testing