— Professional Maintenance & Risk Management Advice from Industry Experience

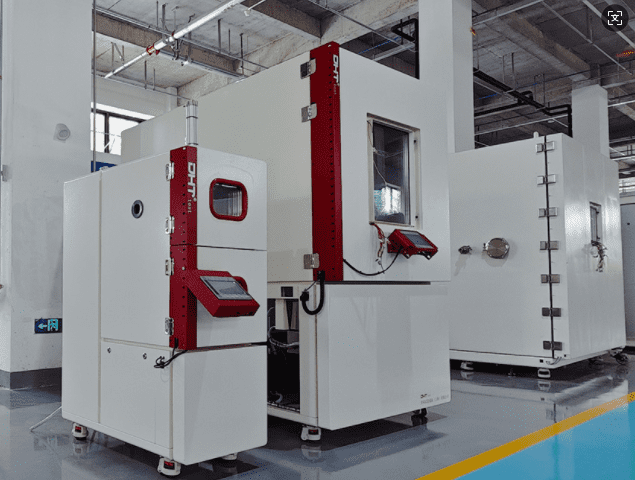

In laboratories, production quality control centers, and research institutions, a constant climate chamber plays a critical role in verifying material weather resistance, electronic component reliability, and product stability.

However, in many cases, performance degradation is not caused by a single failure, but rather by the cumulative impact of subtle, long-term issues—such as water quality, airflow design, power supply stability, and data management discipline.

A real-world example: At an electronics manufacturer, the humidity deviation of a constant climate chamber gradually increased to +4%RH after 18 months of continuous operation. Subsequent inspection revealed that scale buildup in the humidification system reduced evaporation efficiency. The water conductivity had been above 20 μS/cm for months, but the issue went unaddressed. This seemingly minor problem ultimately invalidated the traceability of an entire type-test.

To prevent such costly scenarios, the following maintenance strategy—rooted in real cases and engineering best practices—applies a risk-priority approach rather than a rigid schedule.

Shift from “Fixed Interval” to “Risk-Priority” Maintenance

Many users still rely on fixed maintenance cycles (e.g., monthly cleaning, quarterly inspections). In high-load environments, this can lead to over-maintenance (wasting resources) or under-maintenance (leaving hidden risks).

Recommendations:

- High-risk operating conditions — Continuous operation at extreme setpoints (e.g., 85°C / 85%RH), frequent door openings, 24/7 runtime: shorten cleaning intervals for condensers, lubricate fan bearings more frequently, and inspect door gaskets regularly.

- Medium/low-risk conditions — Some intervals may be extended, but must be paired with online monitoring of temperature/humidity trends. Any deviation should trigger immediate intervention.

Case study: A materials testing lab operating six chambers at high temperature/humidity reduced emergency shutdowns by 68% over three years after implementing risk-priority maintenance.

Water System: The Hidden Lifespan Killer

The humidification system is one of the most overlooked yet critical components of a constant climate chamber. Poor water quality causes scale buildup, microbial growth in the tank, humidity drift, and even sample contamination.

Recommendations:

- Use deionized or distilled water with conductivity ≤10 μS/cm (per ASTM D1193).

- Clean the water tank and humidifier every two weeks to prevent biofilm formation.

- For steam humidifiers, check heating element surfaces for scale buildup and chemically descale as needed.

Case study: An automotive parts manufacturer experienced a +3%RH sensor deviation due to scaling in the water system, leading to a full humidification unit replacement—taking 5 days of downtime and costing over $4,500.

Airflow & Condenser: Ensuring Uniformity and Low Load

Blocked air ducts or dust-laden fan impellers disrupt temperature/humidity uniformity and force compressors to operate under sustained high load.

Maintenance priorities:

- Check return and supply air vents regularly for obstruction by samples.

- For fans with over 2,000 hours of runtime, inspect bearings and replace lubricant or bearings as needed.

- Clean condenser fins quarterly to maintain proper ventilation.

Practical tips:

- Use a portable anemometer to verify airflow. Deviations beyond ±10% of design flow require adjustment or cleaning.

- If condensing pressure rises by 10% or condenser fan current increases by 15%, clean the condenser immediately.

Case study: A third-party testing agency saw its compressor failure rate double in six months due to airflow obstruction from accumulated duct dust.

Electrical System: Stable Power Extends Core Component Life

Compressors, heaters, and control systems are highly sensitive to voltage fluctuations and harmonic distortion. Frequent power disturbances subject electronics to additional thermal stress cycles, accelerating wear.

Recommendations:

- Use a voltage stabilizer or UPS in precision lab environments.

- Check grounding resistance regularly (≤4 Ω recommended) to prevent signal interference.

- Maintain a “Power Event Log” and correlate anomalies with operational data for preventive action.

Safety notes:

- Disconnect power and allow a 10-minute discharge before maintenance; verify zero residual voltage with a tester.

- Wear cryogenic gloves when working on refrigeration lines—evaporator surfaces can reach −70°C.

Data Discipline: The Final Line of Defense for Test Accuracy

Even high-end chambers experience sensor drift over time. Data discipline ensures deviations are detected early and traceable.

Key practices:

- Establish an annual calibration plan and maintain full records (per JJF 1101-2019).

- Randomly compare chamber readings against reference instruments during routine tests.

- Initiate emergency calibration if:

- Temperature/humidity fluctuations exceed ±20% of setpoint, or

- Reference comparison deviation exceeds ±0.3°C / ±2%RH.

Building a “Warning–Response–Verification” Loop

Effective maintenance is not isolated actions—it’s a closed-loop process:

- Warning: Detect potential issues through logs, trend monitoring, or alarms.

- Response: Prioritize and address problems impacting test accuracy first.

- Verification: Confirm resolution via stability tests and archive records.

Conclusion

The lifespan of a constant climate chamber is defined by consistent proper use and scientific maintenance. Even units from the same batch can diverge significantly in performance after a few years—often due to differences in water quality management, airflow condition, power stability, and data discipline execution.

By adopting a risk-priority maintenance plan and paying attention to details in daily operation, you can not only extend your chamber’s service life but also ensure accurate, traceable test data—supporting both R&D and quality control objectives.

If you are seeking higher-performance, lower-maintenance constant climate chambers, or require specialized maintenance advice for your existing equipment, contact the DHT® Technical Team. With years of industry experience and engineering expertise, we provide tailored solutions that make every test more efficient, reliable, and audit-ready.

FAQ

What is the most common cause of performance degradation in a constant climate chamber?

In many cases, performance decline is caused by long-term factors such as poor water quality, airflow obstruction, unstable power supply, and lack of data calibration—rather than a single failure. Addressing these hidden risks through proactive maintenance can significantly extend service life.

How can I prevent humidity deviation in a constant climate chamber?

Use deionized or distilled water with conductivity ≤10 μS/cm, clean the humidification system every two weeks, and check for scale buildup on heating elements. Neglecting these steps can cause humidity drift and even damage critical components.

What maintenance strategy works best for extending a constant climate chamber’s lifespan?

Instead of fixed maintenance intervals, adopt a risk-priority approach—shorten service cycles for high-load conditions, monitor temperature and humidity trends in real time, and act immediately when deviations occur. This method reduces downtime and ensures reliable test data.