Senior Engineer, Doaho Test (DHT®)

Common Salt Spray Test Standards and Test Conditions

- ASTM B117: The most widely used neutral salt spray (NSS) standard globally, applicable to the automotive, aerospace, and electronics industries.

-

ISO 9227: An international standard that defines three test types:

-

NSS (Neutral Salt Spray): Suitable for most metals and organic coatings.

-

AASS (Acetic Acid Salt Spray): Designed for decorative coatings.

-

CASS (Copper-Accelerated Acetic Acid Salt Spray): Used for highly corrosion-resistant materials.

-

-

GB/T 10125-2021: The Chinese national standard, technically equivalent to ISO 9227.

Test Design and Best Operational Practices

-

Sample Preparation: All test samples must be thoroughly cleaned before testing to remove oil, fingerprints, and other contaminants. Surfaces should be dry and of consistent size for comparability. Careful clamping is essential to avoid scratches or damage to coatings or substrates, as these can become initiation points for corrosion.

-

Salt Solution Preparation and Maintenance: A typical solution consists of 5% NaCl by mass. Deionized or distilled water must be used to avoid introducing impurities. Regular checks should be conducted to monitor salt concentration and pH (maintained between 6.5 and 7.2 for neutral tests). Adjustments should be made promptly if deviations are detected. Filtration systems are recommended to prevent nozzle clogging and ensure uniform spraying.

-

Sample Placement: Samples should be positioned at an angle (typically 15°–30°) inside the salt fog chamber to allow the salt spray to run off the surface without pooling. Adequate spacing between samples is required to prevent mutual obstruction. Use inert materials such as plastic, stainless steel, or glass for mounting to avoid contamination from corroded supports.

-

Chamber Settings and Calibration: Test chamber sensors (temperature, humidity, spray systems) must be regularly calibrated to ensure accuracy. For NSS testing, the chamber temperature is typically set at 35 °C. A stable ambient laboratory temperature (around 25 °C) further improves repeatability. Monitor fog density and collection volume throughout the test to maintain a consistent environment and avoid excessive droplet formation.

-

Test Documentation and Evaluation: Test durations must follow the specified standards (e.g., 24h, 48h, 96h, or several hundred hours based on user requirements), with all test parameters recorded in detail. After the test, samples should be rinsed and inspected for corrosion spots, rust spread, and coating performance. Multiple test runs may be necessary to ensure data reliability.

Common Pitfalls and Prevention Strategies

-

Incorrect Water Quality: Using tap water introduces impurities (e.g., calcium, magnesium ions) that can interfere with corrosion processes. Always use deionized water.

-

Contaminated Reagents: Long-stored salt solutions may be contaminated by airborne impurities or microbial growth. Replace or filter regularly to maintain solution purity.

-

Neglected Calibration: Uncalibrated sensors or spray systems can result in inaccurate temperatures or inadequate spray volumes. Establish a routine calibration plan per manufacturer recommendations.

-

Overloaded Samples: Excessive sample loading reduces exposure uniformity and may distort results. Follow chamber capacity guidelines and conduct batch testing if needed.

-

Non-Standard Test Durations: Modifying test durations to save time or cost can result in non-comparable outcomes. Always adhere to the specified exposure time and ensure repeatability by testing at least two samples of the same type and condition for comparison.

Advantages of DHT® Salt Spray Test Chambers

-

Precise Temperature and Humidity Control: Temperature fluctuation within ±0.3°C and uniform atomization.

-

Corrosion-Resistant Construction: Inner chambers made of FRP or high-performance polymers, suitable for long-term testing.

-

Intelligent Operating System: PLC control with touchscreen interface, supporting test programming, data logging, and remote monitoring.

-

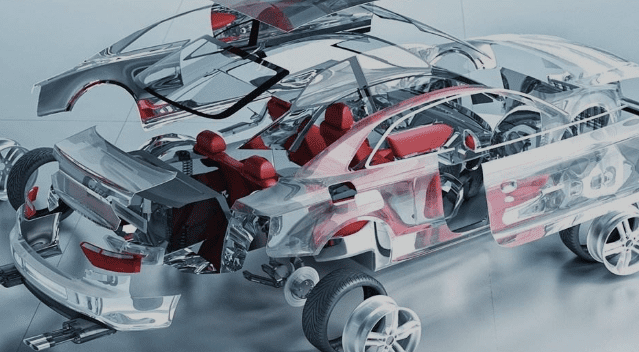

Flexible Customization: Available in a range of models, suitable for testing everything from small fasteners to large body panels.

Conclusion

FAQ

What Are the Main Standards for Salt Spray Testing in the Automotive Industry?

The most common standards include ASTM B117, ISO 9227 (NSS, AASS, CASS), and GB/T 10125-2021. These standards define test types, solution conditions, and duration requirements to ensure comparable corrosion resistance evaluations across different markets.

What Best Practices Ensure Reliable Salt Spray Test Results?

Key practices include thorough sample cleaning, proper salt solution preparation with deionized water, regular monitoring of pH and salt concentration, correct sample placement at 15°–30° angles, chamber calibration, and detailed documentation of test parameters. Following these practices prevents deviations and ensures accurate, repeatable results.

What Are Common Pitfalls in Salt Spray Testing and How Can They Be Avoided?

Typical issues include using tap water instead of deionized water, contaminated or aged salt solutions, uncalibrated sensors, overloading samples, and modifying test durations. These can distort results or make them non-comparable. Preventing such errors requires strict adherence to standards, routine calibration, and disciplined operational procedures.