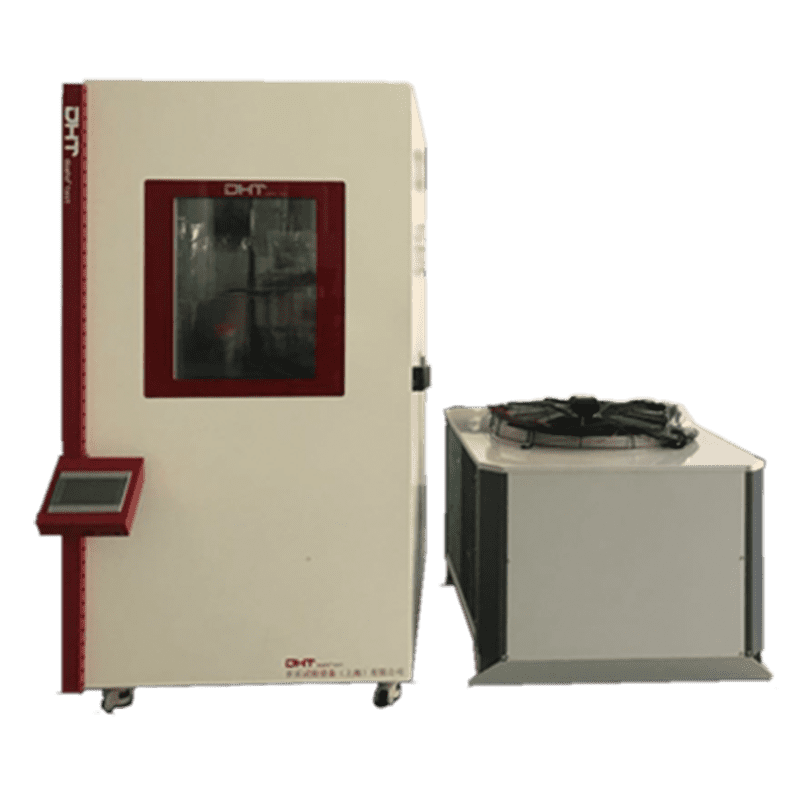

The DHT® Split-Type Temperature Test Chamber revolutionizes large-scale thermal validation through its innovative externally-mounted refrigeration system, which physically separates the high-power compressor unit from the test chamber body. This engineered decoupling achieves a 40-60% reduction in on-site footprint while maintaining uncompromised industrial-grade performance, specifically addressing spatial constraints in metropolitan laboratories, vertical R&D facilities, and dense manufacturing sites.

Equipped with multi-stage cascaded refrigeration (-70°C to +180°C) and turbulence-optimized airflow design, the chamber delivers exceptional temperature uniformity (±0.5°C at steady state) and rapid transition rates (up to 5°C/min), ensuring ISTA 3E, MIL-STD-810H, and IEC 60068-2-1 compliance for high-mass payloads including EV battery packs, aerospace assemblies, and server racks. Advanced features include real-time cloud-based data logging (21 CFR Part 11 optional), dual redundant safety controllers, and seamless integration with factory SCADA/MES systems via PROFINET, providing mission-critical reliability for 24/7 accelerated life testing (ALT), thermal cycling, and failure analysis within automotive, energy storage, and defense supply chains.