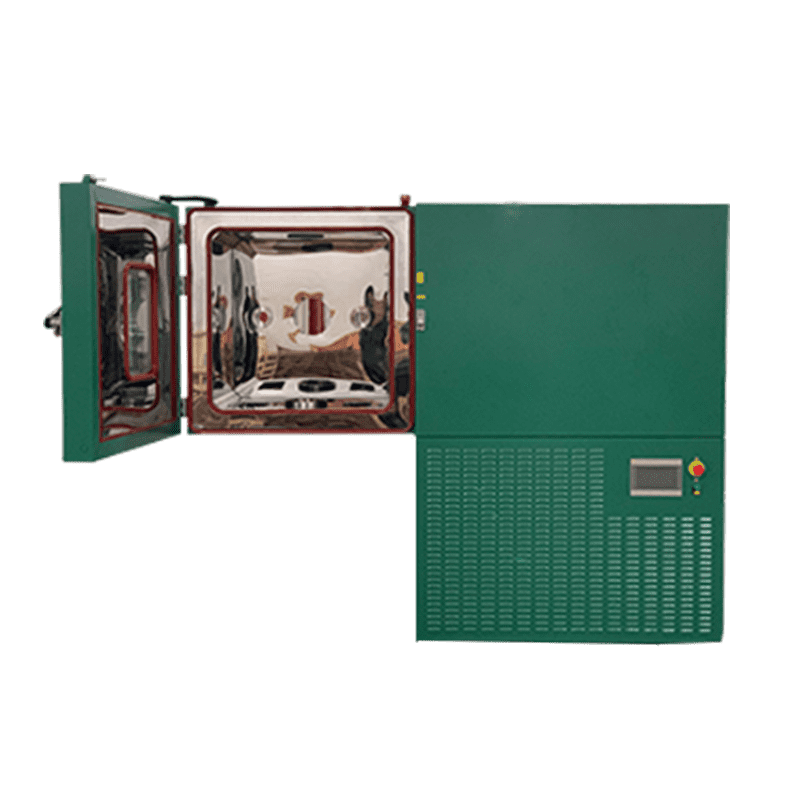

Unlike the Benchtop Vibration Table, which focuses solely on vibration testing, Vibration Testing Chambers offer a more comprehensive functionality. The DHT® Vibration Testing Chamber seamlessly integrates high-precision environmental control with mechanical vibration testing, enabling simultaneous simulation of temperature, humidity, and tri-axial vibration on a single platform.

This combined capability significantly enhances the realism and efficiency of reliability testing. Featuring a modular design, the chamber is compatible with a wide range of vibration table systems and supports sine, random, and shock vibration modes, making it ideal for aerospace, automotive electronics, and defense applications where stringent reliability standards are required. It offers a broad temperature range from -70°C to +180°C and maintains humidity control accuracy within ±2% RH. Powered by DHT®’s proprietary DHSPLCON™ intelligent control system, the chamber supports multi-step programming and real-time data feedback, ensuring excellent repeatability and long-term test stability.

The housing is constructed from corrosion-resistant composite materials, providing superior sealing and anti-interference performance. Advanced features such as safety interlocks, anti-condensation protection, and remote monitoring further ensure reliable operation under demanding multi-stress testing conditions.

To explore common failure modes revealed by vibration testing, read: What Potential Failures Can Vibration Test Chambers Help You Detect?

0/5

(0 Reviews)