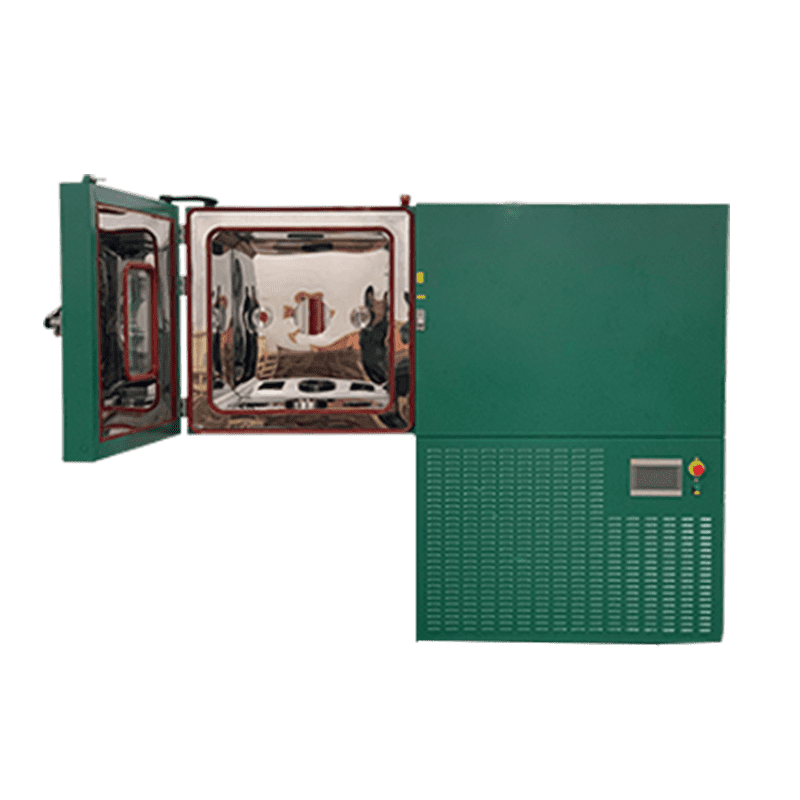

The DHT® VOC Emission Test Chamber is engineered in strict accordance with global testing standards, including ISO 16000, GB 50325, and ASTM D6007, and is specifically designed to accurately quantify the formaldehyde and volatile organic compound (VOC) emissions from building materials, automotive interiors, furniture, and electronic appliances. Featuring a fully sealed 304 stainless-steel chamber (available in volumes from 1 m³ to 30 m³), the system utilizes a dry-wet air mixing method to precisely control environmental conditions—maintaining temperature at 23–40°C (±0.5°C) and relative humidity at 40–60% RH (±3%). A full cross-section horizontal turbulent airflow system ensures excellent spatial uniformity, with temperature and humidity gradients kept within ±5%.

The chamber integrates a four-stage high-efficiency chemical filtration system (≥99.5% removal efficiency for formaldehyde and VOCs) and high-precision imported mass flow controllers (air exchange rate adjustable between 0.2–2.0 ACH, accuracy ±1%), ensuring background contamination levels remain below 5 μg/m³ for formaldehyde and 20 μg/m³ for total VOCs (TVOC). Its intelligent control platform supports real-time data traceability (21 CFR Part 11 compliance optional), dynamic parameter correction, and triple-layer safety protection across the compressor, sensors, and electrical systems. Widely deployed by national quality inspection agencies, leading automotive OEMs, and green building certification laboratories, the DHT® VOC chamber offers a compliant, precise, and reliable solution for environmental emission testing and sustainability validation.