Written by Robin

Senior Engineer, Doaho Test (DHT®)

With increasing global scrutiny on product reliability and safety, IP (Ingress Protection) rating has become a mandatory gateway for product certification and international market access—especially in industries like electronics, automotive, energy, military, and telecommunications.

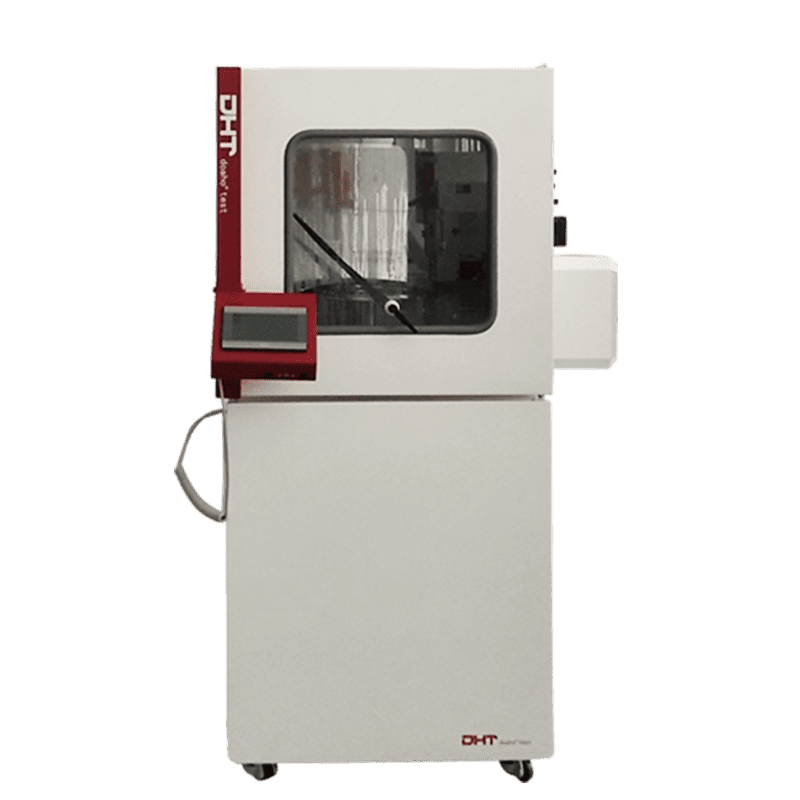

As a core piece of equipment designed to simulate water ingress scenarios, the rain test chamber plays a critical, irreplaceable role in IP testing. However, many companies still perceive it as a simple “spray box,” underestimating its true potential in design validation, quality assurance, and compliance certification.

In this article, we’ll break down:

-

What IP levels a rain test chamber can truly test for

-

Where its technical limits lie

-

Why it’s become a strategic tool for waterproof product design

What Is a Rain Test Chamber and Why Is It Crucial?

A rain test chamber is an environmental testing device that simulates various water intrusion conditions—such as rainfall, water jets, misting, and high-pressure sprays. With programmable spray systems, precise pressure control, and timing mechanisms, it can replicate and even exceed natural environmental conditions to evaluate a product’s sealing, durability, and waterproof integrity.

In the early stages of product design, it helps engineers identify potential sealing flaws (like gasket fatigue or housing gaps). In later phases, it ensures consistency, compliance with industry standards, and customer confidence.

What Waterproofing Tests Are Included in the IP Rating System?

IP ratings, defined by IEC 60529, measure protection against solid and liquid ingress. The second digit (IPX0–IPX9K) specifically refers to water protection:

A rain test chamber typically covers the IPX1–IPX9K range, including:

-

IPX1/IPX2 – Vertical and 15° inclined drip tests

-

IPX3/IPX4 – Simulated rain and multi-angle spray tests

-

IPX5/IPX6 – Medium to high-pressure water jet testing

-

IPX9K – High-temperature, high-pressure water jet (extreme conditions)

These tests aren’t just procedural—they simulate real-world use cases like heavy rain, steam, or industrial washing, making them vital to actual performance validation.

What IP Ratings Can a Rain Test Chamber Actually Support?

IPX1 to IPX4: Standard Drip and Spray Testing

At the core of every rain test chamber is the ability to simulate IPX1 to IPX4 conditions, including:

-

Vertical drip (IPX1)

-

15° inclined drip (IPX2)

-

Oscillating tube rain simulation and swing nozzle spraying (IPX3/IPX4)

-

Multi-angle continuous spraying with automated specimen rotation

Common use cases include consumer electronics (e.g., wearables), home appliances, outdoor lighting, power tools, and power adapters. These tests ensure everyday usability in humid or rainy conditions.

IPX5 / IPX6: Resistance to Medium and High-Pressure Water Jets

Advanced rain test chambers integrate adjustable pressure jet systems that support:

-

IPX5 – 6.3 mm nozzle, 12.5 L/min flow, simulating strong rain or car washing

-

IPX6 – 12.5 mm nozzle, up to 100 L/min, for simulating intense water impact

These tests are essential for automotive lighting, rear-view cameras, control units, outdoor security devices, and enclosures that demand high sealing strength.

IPX9K: Extreme High-Pressure, High-Temperature Water Jets

Premium or custom-built models (such as the DHT® high-performance series) support IPX9K, featuring:

-

Hot water up to 80°C

-

Close-range spray distance (10–15 cm)

-

Multi-angle nozzles (0°, 30°, 60°, 90°)

-

Pressure up to 8–10 MPa with variable timing

Originally developed for automotive use (DIN 40050-9), IPX9K is now widely applied in EV systems, rail infrastructure, military electronics, and equipment exposed to intense cleaning or industrial washdowns.

What Makes a Professional Rain Test Chamber Different?

Compared to basic spray cabinets, a professional rain test chamber offers a wide range of technical capabilities:

-

Multi-pattern Spray Simulation – Switch between linear, fan-shaped, conical, or misting sprays to simulate everything from light drizzle to intense water blasts.

-

Smart Programmable Control – Automate time, spray angle, pressure shifts, cycle counts, and even water temperature for high-throughput or batch testing.

-

Dynamic Sample Movement – Integrated rotary platforms or motorized brackets allow specimens to rotate during testing for comprehensive exposure.

-

High-Precision Monitoring – Sensors for pressure, temperature, flow rate, and humidity ensure accurate, traceable results that meet ISO, GB, ASTM, or MIL standards.

What Industries Rely on Rain Test Chambers?

Rain test chambers are indispensable across high-reliability sectors:

-

Automotive – For headlamps, control modules, charging ports, and rear cameras requiring IPX5–IPX9K protection

-

Consumer Electronics – For smartwatches, earbuds, and mobile phones that meet IPX4–IPX8 standards (often combined with immersion tests)

-

Renewable Energy – For outdoor inverters, junction boxes, and metering equipment exposed to prolonged wind and rain

-

Military & Security – For field comms and surveillance systems that must operate in extreme environments

-

Lighting & Building Automation – For outdoor fixtures, smart locks, and access systems exposed to long-term environmental stress

Does Not Having a Rain Test Chamber Affect Certification or Delivery?

Absolutely—yes. Lacking in-house rain testing capability can hinder your:

-

Export Compliance – Certifications such as CE (Europe), UL/CSA (North America), and CCC (China) often require validated IP data

-

Customer Audits – OEMs and Tier-1 suppliers frequently audit sealing performance and lab capabilities during supplier qualification

-

Tender Participation – Government and infrastructure projects typically require IP certification via third-party labs

-

Brand Reputation – Promoting waterproof claims without real test data risks recalls, complaints, and legal exposure

Whether you own a chamber or partner with an accredited third-party lab, rain testing capability is now a global compliance baseline.

Conclusion: The Rain Test Chamber Is Your Waterproofing Litmus Test

As products become more outdoor-oriented, miniaturized, and smart, waterproofing is no longer an optional feature—it’s a core quality metric that defines product lifespan, user experience, and brand credibility.

A rain test chamber isn’t just a tool—it’s a gateway to reliability:

-

It helps engineers uncover flaws early.

-

It ensures consistency in manufacturing.

-

It safeguards the product before delivery.

Whether you’re entering global markets or undergoing supplier audits, a rain test chamber is your frontline defense in waterproofing assurance.

If you’re considering integrating one—or want guidance on customization—contact the DHT® team to build a water ingress strategy that meets the demands of your market and exceeds expectations.

People also ask

What IP Ratings Can a Rain Test Chamber Handle? Does It Support IPX9K?

Yes. Rain test chambers support IPX1 to IPX9K, covering everything from vertical drips to high-pressure, high-temperature water jets. IPX9K is one of the most stringent water ingress tests, widely used in automotive, defense, and renewable energy industries.

My Product Isn’t Automotive or Military—Do I Still Need Rain Testing?

Yes. Any product exposed to outdoor, humid, or splashing environments—such as wearables, tools, adapters, or lighting—should undergo IP testing via a rain test chamber. It helps expose design flaws and boosts product reliability.