What Is a Fast Change Rate Chamber?

-1-300x300.png.webp)

-

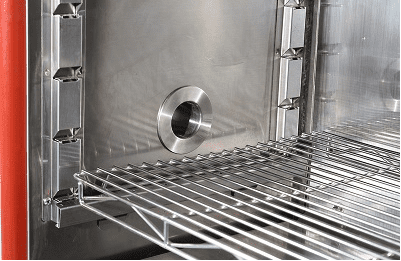

Single-zone chambers, which perform rapid heating and cooling in one chamber, are ideal for standard testing.

-

Three-zone chambers use mechanical transfer systems to shuttle test samples between hot, ambient, and cold zones, making them ideal for thermal shock applications.

Why Is Rapid Temperature Change Testing So Critical?

-

Identifying Potential Product Failures Early This type of testing allows manufacturers to detect design flaws, material inconsistencies, and assembly defects early in the development cycle. Common failure modes include solder joint fatigue, PCB trace fractures, microcracks in plastic housings, adhesive failure, and sealant degradation. It also reveals issues like delamination due to mismatched thermal expansion coefficients between materials—helping to prevent costly quality issues in mass production.

-

Meeting Industry Standards Rapid temperature testing supports compliance with a range of global industry standards, including:

-

-

MIL-STD-883 (military electronics)

-

IEC 60068-2-14 (general electronics)

-

JEDEC JESD22-A104 (semiconductors)

-

ISO 16750-4 (automotive electronics)

-

Passing these tests not only ensures product reliability but also plays a key role in gaining international certifications and market access. -

-

Extending Product Lifespan & Reducing Warranty Claims By simulating years of environmental wear and tear within days or weeks, rapid temperature cycling helps predict long-term performance, reduce failure rates, and improve brand reputation—all while lowering service costs and improving customer satisfaction.

-

Ensuring Microcomponent Reliability As products become increasingly compact and modular, their internal structures are more sensitive to thermal expansion and contraction. This makes rapid temperature change testing especially critical for micro-components like chips, MEMS sensors, and lithium batteries, where thermal stress can significantly impact performance and safety.

How to Choose the Right Chamber for Your Business Stage

-

Startups: Focus on scalability. Opt for modular systems that meet baseline needs (e.g., -40°C to +130°C) but can be upgraded to more advanced ranges (e.g., -70°C to +180°C) as your requirements grow.

-

Established Manufacturers: Build an integrated testing ecosystem. Connect chambers to MES systems for streamlined workflows—from barcode scanning and automated test programming to real-time data logging and report generation.

-

High-End R&D Labs: Prioritize extreme performance. Semiconductor companies, for instance, may require 30°C/min ramp rates using liquid nitrogen cooling to simulate heat buildup in 3D packaged chips.

-

Beware of “Spec Sheet Traps”: One lab fell into this common pitfall—relying on a listed ramp rate of 15°C/min without noting it was for an empty chamber. When testing a fully loaded automotive ECU, the real-world ramp rate dropped to 5°C/min, resulting in invalid test results and wasted time.

The Future of Rapid Temperature Testing

“After 1,500 cycles from -40°C to +105°C, we discovered thermal noise issues in our CMOS image sensors at around 85°C. That insight led us to redesign the heat dissipation path, improving our night vision system’s signal-to-noise ratio by 47%.” — Chief Engineer, Automotive Camera Manufacturer

Conclusion: Building the Foundations of Reliability

“We’re not testing temperatures—we’re testing the dignity of our products under pressure.”

FAQ

What Is a Fast Change Rate Chamber?

A fast change rate chamber is a specialized environmental test device designed to expose products or materials to rapid and frequent temperature fluctuations under controlled conditions, with change rates from 3°C to 30°C per minute. It helps replicate real-world thermal extremes such as high-altitude flight, cold-starts, and harsh climate transport.

Why Is Rapid Temperature Change Testing Critical for Product Reliability?

Rapid temperature cycling helps identify design flaws, material inconsistencies, and assembly defects early, ensuring microcomponent reliability, extending product lifespan, reducing warranty claims, and supporting compliance with international standards like MIL-STD-883, IEC 60068-2-14, and JEDEC JESD22-A104.

How Should Companies Choose the Right Fast Change Rate Chamber?

Selection depends on business stage and product needs: startups may opt for modular systems with scalable ranges, established manufacturers benefit from integrated testing ecosystems with real-time monitoring, and high-end R&D labs may require extreme ramp rates for microelectronics and semiconductor applications.