In today’s highly competitive manufacturing landscape, product reliability has become a crucial measure of a company’s core competitiveness. Whether in automotive electronics, aerospace, telecommunications, new energy batteries, or medical instruments, customers demand ever-increasing levels of product stability and longevity. For manufacturers, the challenge lies in ensuring that products can withstand real-world conditions while balancing time and cost constraints. HASS—Highly Accelerated Stress Screening— provides one of the most effective solutions to this challenge.

Definition and Background of HASS

HASS, or Highly Accelerated Stress Screening, is a testing methodology that subjects products to stress levels beyond normal operating conditions—such as temperature, humidity, vibration, and electrical load—in order to reveal latent defects within a short period of time. In simple terms, HASS does not aim to destroy the product but rather to apply controlled, accelerated stress within a safe margin to expose potential weaknesses early during mass production.

The theoretical foundation of HASS lies in HALT (Highly Accelerated Life Testing). HALT is applied during the R&D phase to uncover design limits and structural weaknesses. HASS, on the other hand, is implemented in the production phase, using the product’s known operating and destructive limits to establish safe stress profiles that effectively screen out latent manufacturing defects. Together, HALT and HASS form a complementary reliability verification system.

Core Objectives of HASS

- Identify latent manufacturing defects

Even if a product design is sound, mass production may introduce issues such as inconsistent component quality, soldering defects, or assembly deviations. HASS aims to uncover these hidden weaknesses early. - Reduce infant mortality failures

Many electronic products follow a “bathtub curve” failure model, where the highest risk of failure occurs in the early stages of use. HASS helps eliminate these early-life failures, ensuring that only reliable products reach customers. - Enhance product reputation and competitiveness

Products that undergo HASS screening are more resilient to environmental stresses—such as temperature fluctuations and vibration—encountered during use, significantly reducing warranty claims, repairs, and recalls.

Implementation of HASS

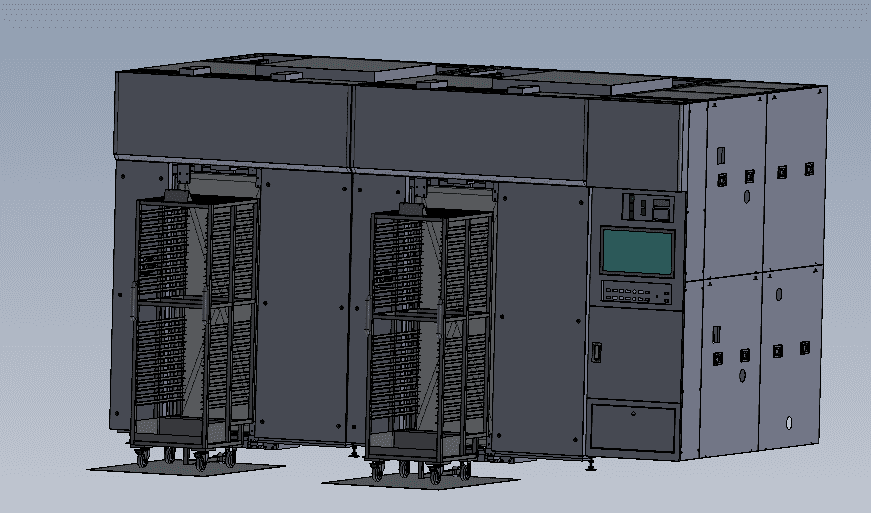

HASS typically relies on advanced environmental test chambers, such as temperature chambers, temperature and humidity chambers, vibration systems, or combined stress chambers. A complete HASS process usually involves:

- Defining stress limits

Stress levels are determined based on HALT results. Engineers select ranges slightly below destructive limits but high enough to trigger latent defects. - Applying thermal stress

Rapid thermal cycling accelerates material expansion and contraction, revealing weaknesses in solder joints, packaging, and bonding processes. - Applying vibration stress

Random or shock vibration simulates transportation, installation, and operational stresses, exposing mechanical integrity issues. - Combined stress testing

In certain industries, HASS combines thermal and vibration stress, and sometimes adds electrical stress, to better replicate real-world conditions. - Screening and evaluation

Products that survive stress cycles without functional degradation proceed to the next stage or shipment, while failures are removed and analyzed for quality improvement.

Advantages of HASS

Compared with conventional quality checks (such as sampling or burn-in testing), HASS offers significant benefits:

- Efficiency: Uncovers defects in a much shorter time compared to traditional burn-in tests.

- Comprehensiveness: Simultaneously applies multiple stresses, closely simulating real-world usage.

- Cost-effectiveness: Although requiring investment in test equipment, HASS significantly reduces long-term costs from recalls and warranty claims.

- Preventive capability: Identifies not only faulty units but also underlying process flaws, enabling continuous quality improvement at the source.

Applications of HASS Across Industries

- Automotive electronics: ECUs, sensors, and safety-critical modules require maximum reliability; HASS is an essential step before shipment.

- Aerospace: Flight control systems and navigation equipment undergo HASS to ensure stable performance under extreme conditions.

- Telecommunications: Base station modules and optical components benefit from HASS to minimize early failures in long-term operation.

- New energy: Power batteries and BMS systems screened through HASS show improved safety and reduced early failure rates.

- Medical devices: Critical systems such as monitors and ventilators undergo HASS to guarantee dependable performance in complex environments.

The Role of Test Chambers in HASS

The success of HASS is closely tied to the performance of environmental test chambers, which serve as the backbone of stress screening:

- Temperature chambers: Deliver rapid thermal cycling to simulate extreme hot and cold environments.

- Temperature and humidity chambers: Validate the effect of humidity on electronic components and bonding materials.

- Vibration systems: Apply multi-axis vibration to mimic transportation and operational conditions.

- Combined stress chambers: Integrate temperature, humidity, and vibration for advanced screening in high-tech industries.

For chamber manufacturers, offering HASS-capable equipment reflects technical strength and industry leadership. For end users, selecting and configuring the right chambers is a critical investment in product reliability.

Conclusion and Outlook

HASS (Highly Accelerated Stress Screening) is a proven and powerful reliability enhancement methodology. By rapidly identifying and removing latent defects during mass production, it reduces infant mortality rates and improves overall product quality. Together with HALT—focused on R&D—HASS safeguards reliability throughout the entire product lifecycle.

As industries such as 5G, renewable energy, and intelligent manufacturing advance, products are becoming increasingly complex, with higher reliability demands. The role of HASS will continue to expand in importance. For enterprises, mastering and effectively implementing HASS is not just a quality assurance measure but a strategic advantage in global competition.

If your industry involves electronics, electrical systems, machinery, or high-tech manufacturing, HASS is more than a screening process—it represents a culture of reliability. Only by embedding it into R&D, production, and quality management can companies stand out in an increasingly demanding market.

FAQ

Q1: What is HASS and how does it differ from HALT?

A1: HASS (Highly Accelerated Stress Screening) is a production-stage reliability test that applies stresses such as temperature, vibration, and humidity beyond normal operating levels to expose latent defects. Unlike HALT, which is performed during R&D to find design limits, HASS is used in mass production to identify and eliminate weak units before shipment.

Q2: What are the main benefits of implementing HASS?

A2: HASS reduces early-life failures (infant mortality), ensures only reliable products reach customers, minimizes warranty claims and recalls, and improves overall product quality and reputation. It also provides preventive insights into process flaws, enabling continuous manufacturing improvement.

Q3: What equipment is required to perform HASS?

A3: HASS relies on advanced environmental test chambers, including temperature chambers, temperature and humidity chambers, vibration systems, and combined stress chambers. These tools simulate real-world conditions by applying thermal, mechanical, and sometimes electrical stresses to detect hidden defects.