Why Full-Vehicle Validation Requires a Walk-In Environmental Chamber?

-

Accommodates entire vehicles (passenger or commercial) or large integrated systems

-

Simulates a wide range of extreme environments: temperature (-40°C to +80°C), humidity (10%–98% RH), wind speed, rain, and low atmospheric pressure

-

Supports testing for battery thermal runaway, high-voltage system stability, high-heat exposure, cold-start conditions, and more

-

Suitable for various stages including prototyping, regulatory certification, and long-term durability validation

Practical Applications: Real-World Value of Walk-In Chambers

-

Full-Vehicle Thermal Performance Testing

-

Cold-start testing at temperatures as low as -30°C

-

High-load system operation under heat conditions up to +70°C

-

Rapid thermal cycling to assess component stress and system resilience

-

Battery and High-Voltage System Testing

-

Full-vehicle thermal aging and thermal management assessments

-

Simulation of thermal runaway events and mitigation strategies

-

BMS, inverters, and drive systems tested under dynamic temperature and humidity

-

Water & Dust Resistance Validation

-

Evaluating water ingress in door seals, sunroofs, and cable entry points

-

Simulating high-wind, dust-laden environments

-

Conducting IPX4, IP5X, and IP6K ingress protection certification tests

-

Material Aging & VOC Emission Testing

-

UV exposure, alternating heat-humidity stress cycles

-

Dynamic VOC emission changes (TVOC, formaldehyde, etc.)

-

Long-term aging of trim, adhesives, and sealing materials

Cost-Effectiveness: Long-Term ROI of Walk-In Chambers

-

Streamlined Testing, Shorter R&D Cycles

-

Lower Total Cost of Ownership

-

Avoiding redundant purchases and energy costs from multiple systems

-

Minimizing manpower and time lost to repeated test configurations

-

Reducing outsourced testing fees—especially critical for confidential projects

-

High-Value Data Integration

-

High-resolution environmental and operational test data

-

Accurate root cause analysis and design optimization

-

Data-backed insights for after-sales improvements and product reliability

-

Compliance-Ready Testing Infrastructure

-

Test scope and protocol compliance

-

Certification speed and approval success rates

-

Global market accessibility

Who Should Consider a Walk-In Environmental Chamber?

-

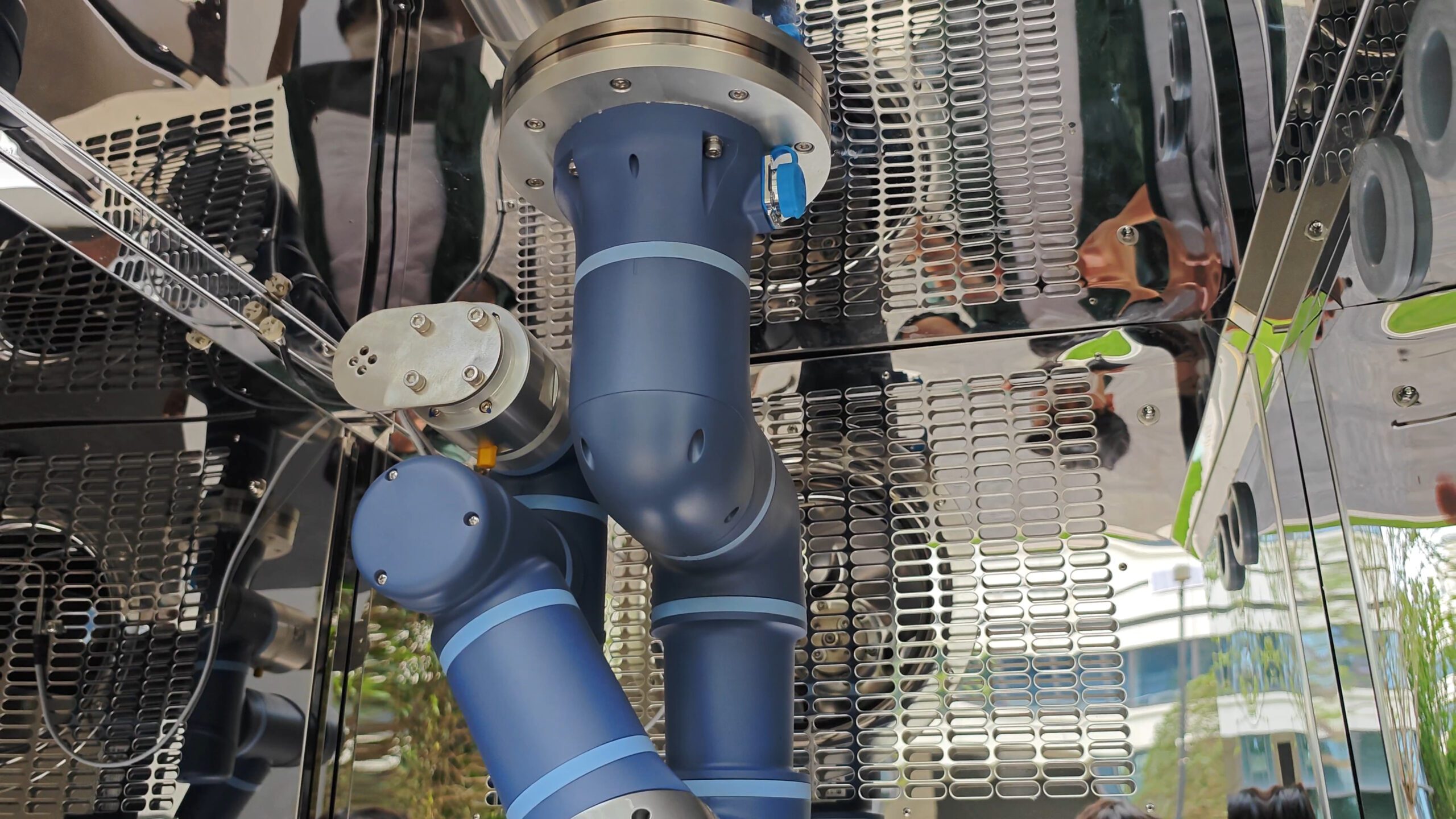

Vehicle OEMs & Tier-1 Suppliers: For full-vehicle or integrated system testing

-

EV System Manufacturers: For battery packs, HVAC, and high-voltage architecture validation

-

Autonomous Driving & Smart Cockpit Developers: To test sensors, cameras, and control units in extreme environments

-

Third-Party Testing Labs: Offering environmental testing services to OEMs and component manufacturers

-

Special Vehicle & Custom Coach Builders: For high-altitude, polar, or military-grade environmental performance validation

Conclusion: Creating Controlled Extremes for Global Automotive Readiness

FAQ

Why Do Automotive Manufacturers Need Walk-In Environmental Chambers?

Because vehicles are highly integrated systems, component-level or subsystem tests cannot fully replicate real-world performance. A walk-in chamber allows full-vehicle validation under extreme conditions such as temperature from -40°C to +80°C, humidity up to 98% RH, wind, rain, and low pressure, ensuring safety, reliability, and compliance.

What Types of Tests Can Be Conducted in a Walk-In Environmental Chamber?

Walk-in chambers support full-vehicle thermal performance testing, battery and high-voltage system validation, water and dust ingress certification, material aging studies, and VOC emission analysis. They simulate multiple extreme conditions—cold starts, thermal runaway, UV exposure, and combined humidity-temperature cycles.

What Are the Cost and Efficiency Benefits of Using Walk-In Chambers?

Although walk-in chambers require higher upfront investment, they reduce long-term costs by consolidating multiple tests into one setup, shortening R&D cycles, lowering outsourced testing fees, and improving certification readiness. Integrated data collection also supports root cause analysis, design optimization, and global market compliance.