Written by Shirley

Product Manager, Doaho Test (DHT®)

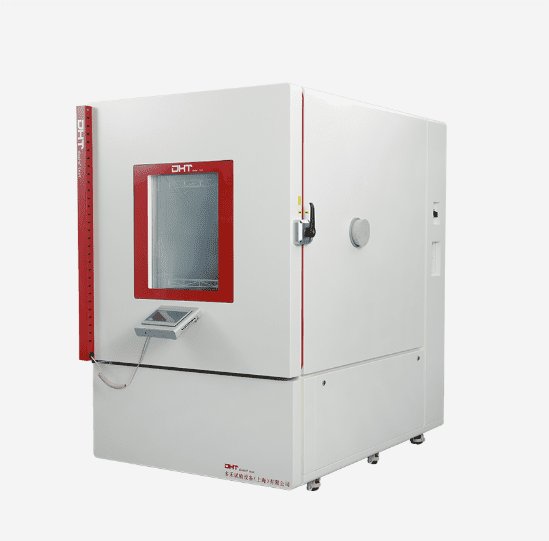

Traditionally, larger equipment is associated with stronger performance and broader functionality, while smaller benchtop models are seen as suitable for limited budgets or less demanding tests. However, as testing requirements become more diverse and laboratory space grows increasingly scarce, an increasing number of high-tech R&D institutions, electronics manufacturers, and university labs are turning their attention to benchtop environmental chambers.

This article explores five typical application scenarios to analyze why benchtop environmental chambers have emerged as a highly cost-effective choice, redefining the value of small-scale devices in terms of functionality, testing efficiency, and return on investment.

R&D Verification Stage: Ideal for High-Frequency, Small-Batch Testing

In the early stages of new product development, teams often conduct frequent temperature and humidity cycling tests to evaluate structural integrity, electrical performance, and material stability. During this phase, test samples tend to be small and limited in quantity, making the large volume of walk-in chambers prone to underutilization and resource waste.

In contrast, benchtop environmental chambers feature rapid temperature ramp rates and precise environmental controls, making them highly efficient for short-cycle, low-volume testing tasks. Their quick startup and minimal preheating time significantly enhance R&D testing efficiency, making them indispensable tools for prototype validation and iterative design.

Space-Constrained Laboratories: Compact Design Maximizes Usable Workspace

For university labs and corporate R&D centers, space is often at a premium with high-density equipment setups. Compared to the large footprint of walk-in chambers, benchtop environmental chambers can be conveniently placed on workbenches or lab tables, conserving valuable floor space.

Moreover, many benchtop models support stacking or modular expansion, enabling laboratories to build multi-station parallel testing systems and greatly increase throughput per square meter while maintaining operational flexibility.

Small to Medium Enterprises and Startups: Lower Initial Investment, Higher Cost Efficiency

Budget constraints are common challenges for SMEs, renewable energy startups, and academic research projects. The high upfront cost of walk-in chambers can be prohibitive, whereas benchtop chambers offer a more affordable entry point to establish basic environmental testing capabilities.

Modern benchtop environmental chambers deliver control precision, data acquisition, and remote monitoring capabilities comparable to larger models, adequately meeting the environmental qualification needs of most electronic components, material samples, and optical assemblies — balancing performance with cost-effectiveness.

Precision Testing Requirements: Avoid Over-Engineering and Boost Efficiency

Not all testing scenarios demand large-scale equipment, especially when high temperature and humidity control accuracy and stable parameters are critical. In such precision applications, walk-in chambers may lead to excessive space and energy consumption.

For example, in testing IC packages, MEMS sensors, or LED assemblies, the smaller chamber volume of benchtop units promotes more uniform temperature and humidity distribution and faster response times, ensuring greater repeatability and reliability of test results.

Multi-Point Parallel Testing: Flexible Expansion and Rapid Deployment

In manufacturing and reliability labs, there is often a need to operate multiple test points simultaneously or replicate equipment for parallel verification. Walk-in chambers are typically constrained by cost and space, making rapid expansion challenging.

Benchtop environmental chambers, with their portability, ease of installation, and simple operation, excel at enabling multi-point layouts and flexible scalability. Deploying multiple benchtop units across production floors supports concurrent accelerated aging and environmental adaptation tests for diverse sample batches, significantly enhancing quality control and process optimization efficiency.

Benchtop Environmental Chambers: Small Footprint, Big Performance — The Future of Environmental Testing

With ongoing improvements in control accuracy, response speed, and intelligent automation, benchtop environmental chambers are no longer synonymous with limited functionality. Their compact size, flexibility, efficiency, and cost control enable them to replace traditional walk-in chambers in a growing number of scenarios, becoming indispensable tools in research and manufacturing.

Whether for space-limited, budget-conscious labs or forward-thinking enterprises pursuing high efficiency and modular deployment, benchtop environmental chambers offer compelling, competitive solutions.

When selecting equipment, users should consider their specific testing requirements, sample sizes, performance criteria, and spatial constraints to make an informed choice. For teams aiming to quickly establish reliable testing capabilities with minimal investment, benchtop environmental chambers undoubtedly represent a smart and strategic option.

For detailed technical specifications, industry suitability, or brand recommendations, please feel free to

contact us. We are committed to providing professional, customized solutions tailored to your unique needs.

FAQ

What are the advantages of a benchtop environmental chamber for R&D labs?

Benchtop chambers offer fast temperature cycling, precise environmental control, and compact design—ideal for frequent, small-batch prototype testing in space-constrained R&D labs.

Is a benchtop environmental chamber suitable for startups or small businesses?

Yes, benchtop chambers provide a cost-effective testing solution with professional-grade performance, requiring lower upfront investment while meeting most electronic and material test needs.

Can benchtop chambers replace walk-in chambers in high-precision applications?

Absolutely. For tasks requiring high control accuracy—like IC, MEMS, or LED testing—benchtop chambers offer better uniformity, faster response, and lower energy use than oversized walk-in models.